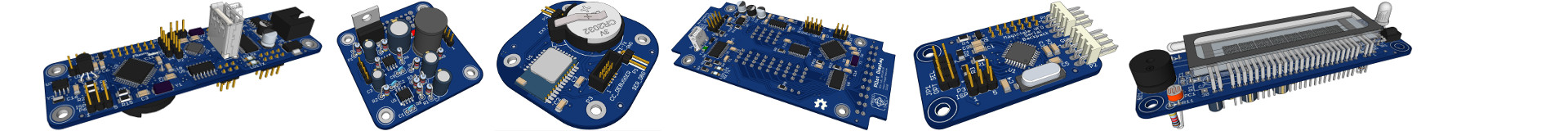

Continuing the development cycle of the BlueButton today we are going to create an enclosure prototype which potentially could be 3D printed. The goal would be to fit PCBA into a plastic box comprising of three parts: a top shell, a bottom shell and a round button. All 3D bodies will be created by extrusion of profiles along two paths as shown on the picture below. The profiles are made no less than 2.5 mm which would correspond the thickness of plastic walls. The bottom shell is going to have four moulded standoffs to support PCBA, the top and bottom shells will be held together with friction. The round button would have a funnel-like hole at its centre letting the LED shine through.

The PCBA will be secured onto the bottom shell with self-tapping 3mm screws. The round button will rest on tactile switches’ actuators as shown on the picture below.

The exploded assembly is given below.

And the final result of a fully assembled BlueButton is shown below.

A 3D model of the enclosure with PCBA is provided below.

Leave a Reply

You must be logged in to post a comment.