Grand Prize Winner

(Dec 2012)

Second Prize Winner

(July 2012)

Donations Development in general requires time and money. Development of opensource projects is not an exception. To keep this online resource alive we heavily rely on your donations. If you feel like supporting us please make a donation.

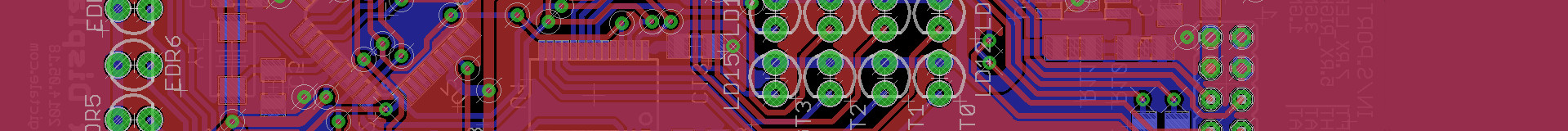

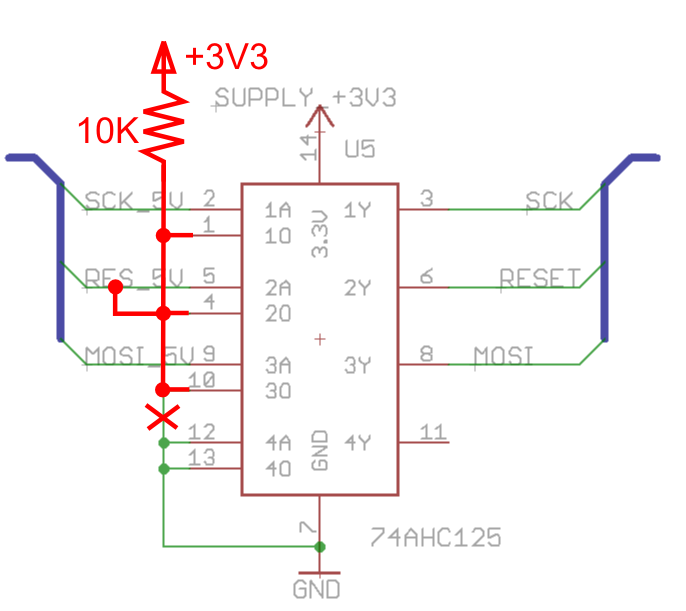

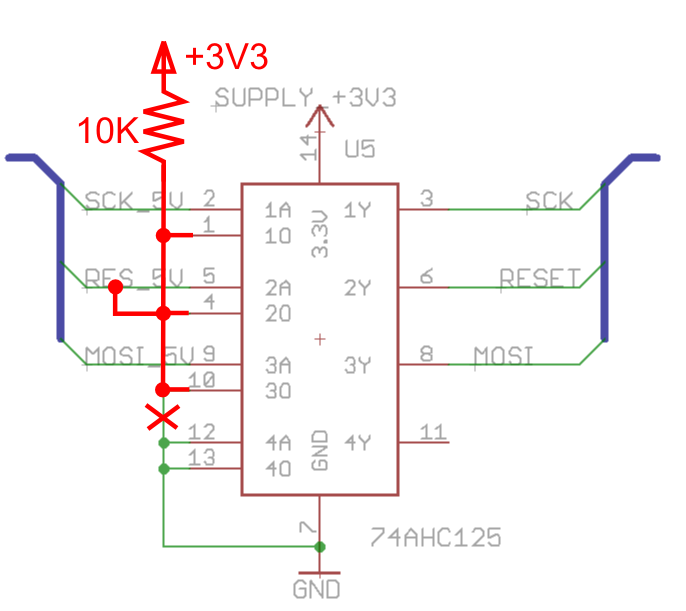

First Luminardo prototype has been assembled and tested. As it usually happens, first revision is not without flaws. There are two issues with circuit diagram, one issue with component footprint, a few typos in BOM as well. First and the most annoying issue is related to 74AHC125 buffer (U5) which outputs never go to high impedance state causing conflicts on SPI bus and reset line. As a result, it is possible to program ATMega chip via ISP but after it indefinitely remains in reset state even with ISP programmer disconnected as the buffer pulls ‘RESET’ low. Solution is simple, buffers outputs should be active only during programming procedure, in other words, when ‘RES_5V’ is pulled low. As 1, 4 and 10 inputs work as ‘output enable’ lines which active LOW level, it means that they should be driven by ‘RES_5V’ instead of just being connected to GND. Additional pullup resistor should explicitly put the outputs to Hi-Z state when nothing is connected to ISP connector. The required modifications are shown on the picture below.

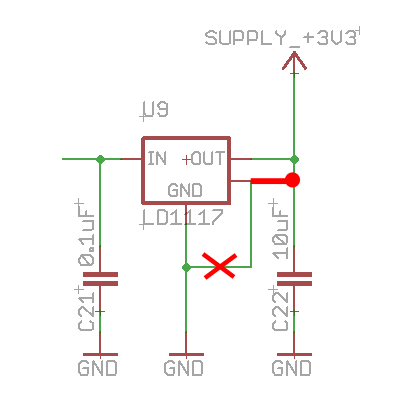

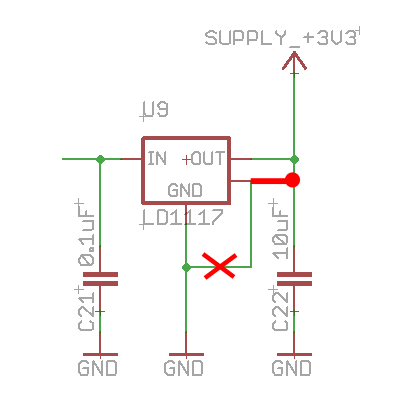

Luminardo Rev 1.0 Circuit Fix 1 The second problem is related to LD1117 (U9) voltage regulator, its TAB pin is actually internally connected to Vout and in our case it was the cause of short circuit. The required modification is shown on the picture below.

Luminardo Rev 1.0 Circuit Fix 2 And finally, there is an error with temperature sensor (U1) footprint, first and third pins are swapped, currently fixed by 180 degrees rotation of the component.

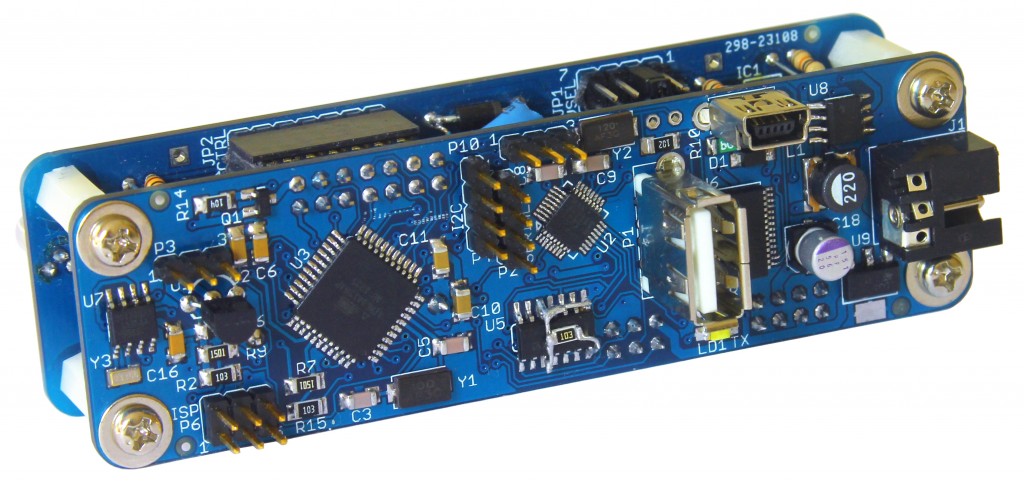

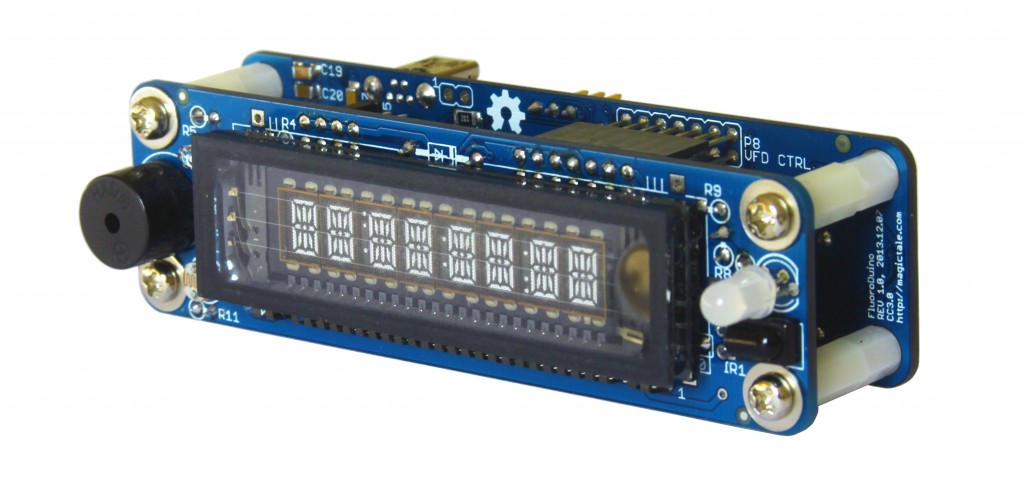

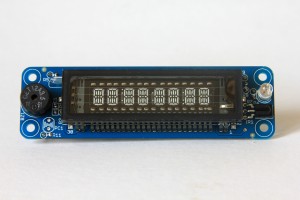

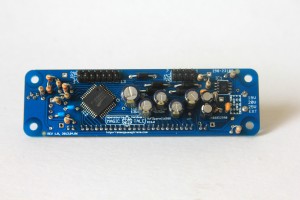

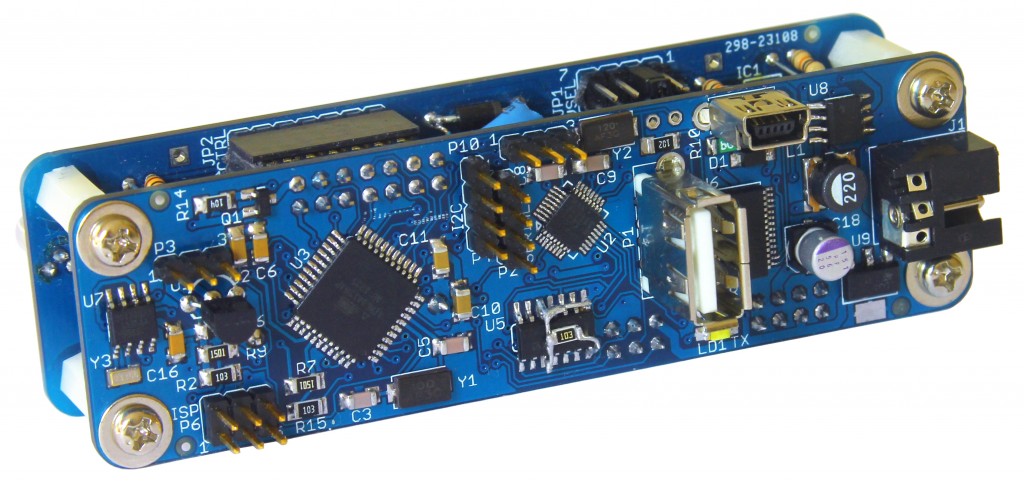

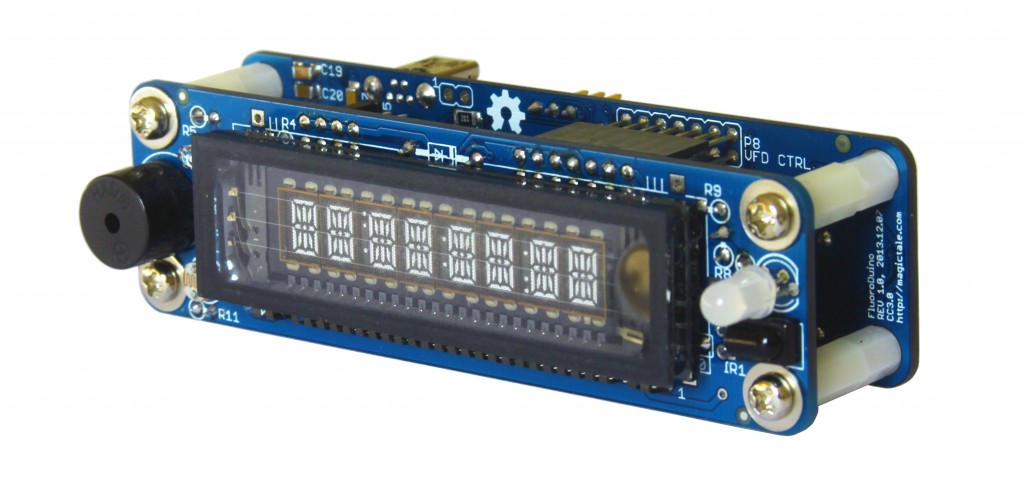

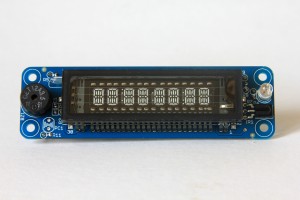

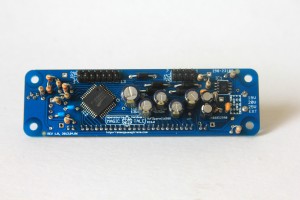

All in all, the first PCB has been successfully soldered with the abovementioned fixes and fully tested (except for 12-5V DC-DC convertor). The assembled PCB with MVFD 16S8D Module attached is shown on the pictures below:

Luminardo Assembled Prototype Rear ISO View Rev1.0  Luminardo Assembled Prototype Front ISO View Rev 1.0 More information will come very soon, stay tuned.

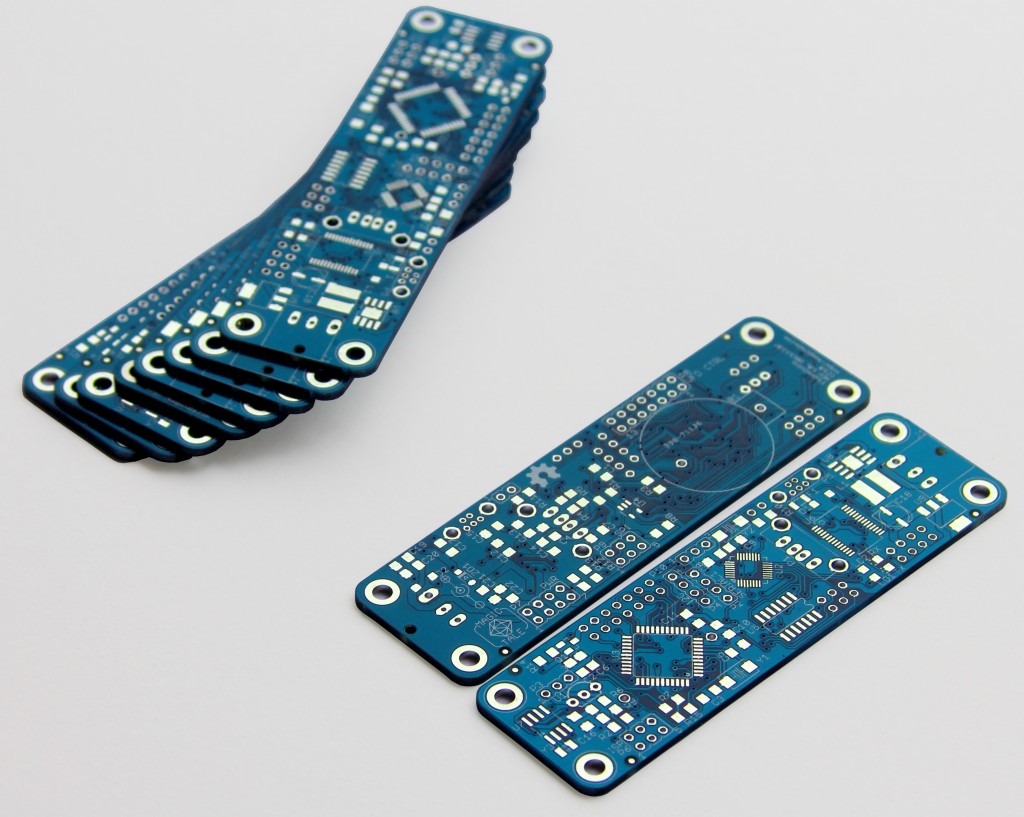

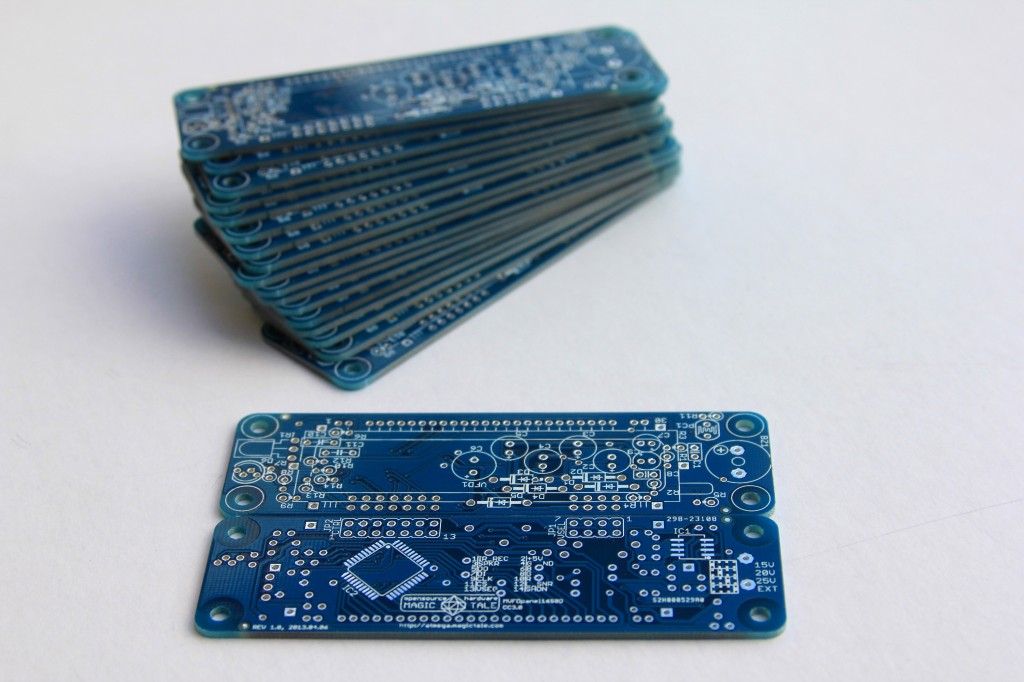

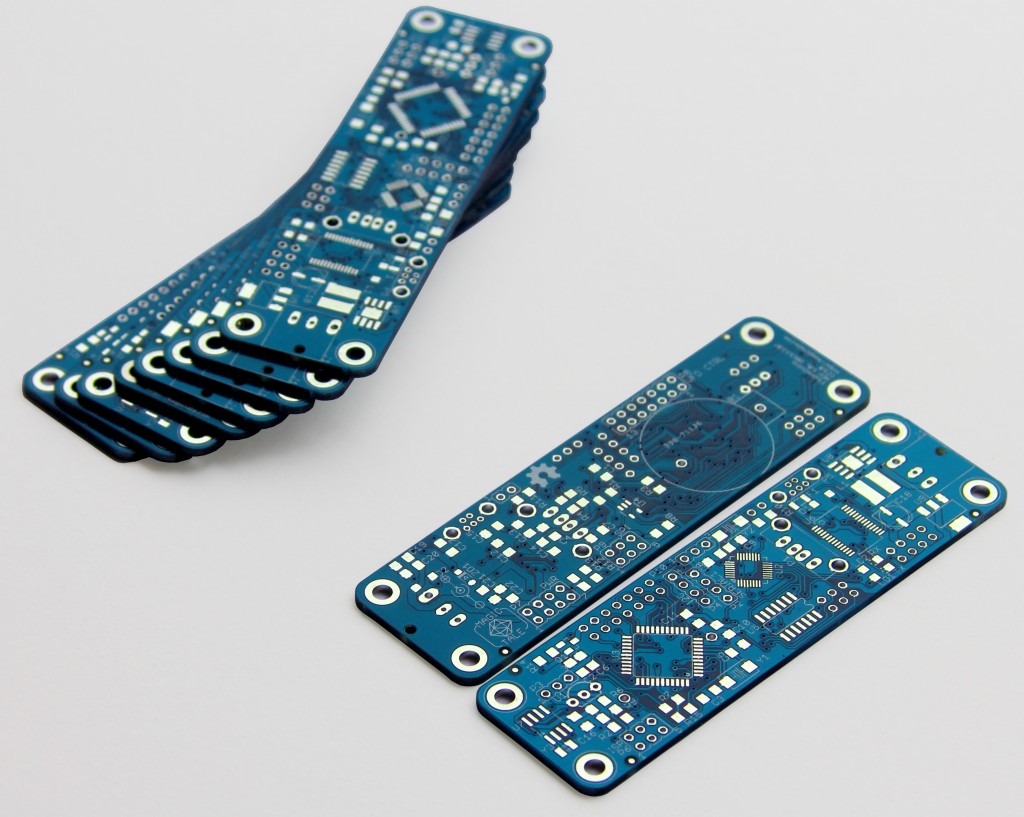

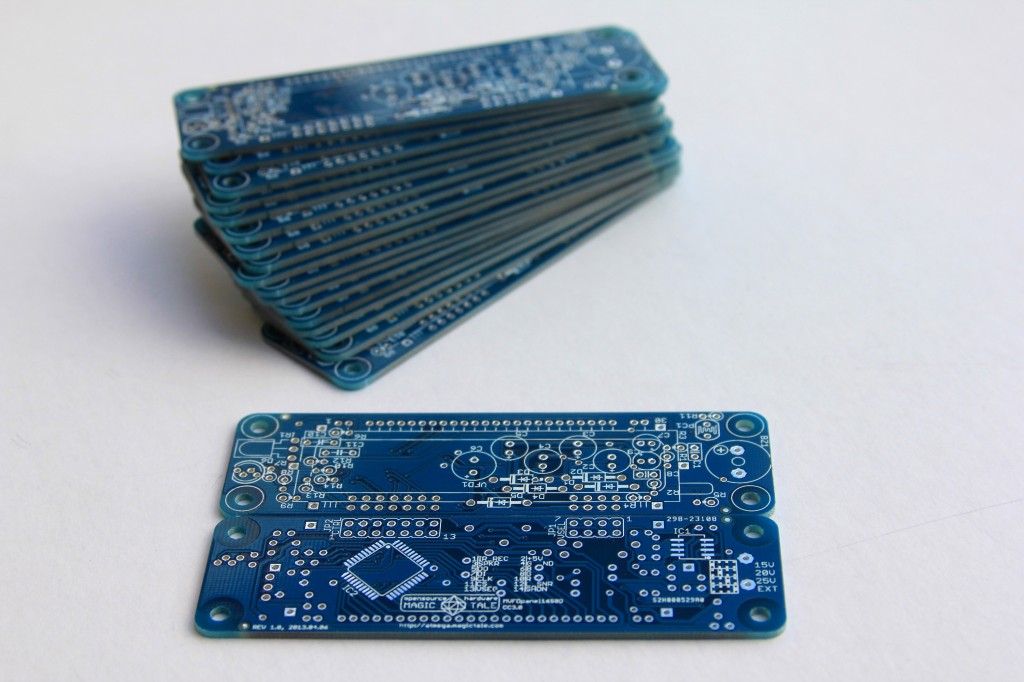

Luminardo Rev.1.0 PCBs finally arrived so we will be busy this Christmas soldering and debugging. Nothing terribly wrong at this point in time, everything seems to be free from design flows and fabrication faults. The only issue that has been noticed so far is that the manufacturing house for some reasons yet unknown failed to draw ‘Luminardo’ bitmap on top silkscreen, not that it impacts functionality in any way. And what is more curious, this time we received only 10 PBCs while last time they made 20 MVFD boards with the same dimensions. So ITeadStudio is kinda inconsistent in its manufacturing process.

This is how the PCBs look:

Luminardo Rev1.0 Bare PCBs Wait for more upcoming updates on this topic and Merry Christmas/Happy New Year!

Today we literally bumped into this extremely cheap mini remote control at Reject Shop in Parramatta Westfield. The RC costs just 3 Australian dollars and it includes CR 2032 button cell battery. Even without the battery it would’ve been too cheap so this offer looked to us very suspicious. That is why we bought two of them to put under test. This is what the RC looks like:

Mini Remote Control from Reject Shop for just 3 AUD Our MVFD Panel was used to test the RC, this is how the test setup looks like:

Mini Remote Control Test Setup MVFD panel can handle packets encoded in either NEC, SONY, RC5 or RC6 IR standards. And on top of that, if it detects something vaguely similar to IR data rather than just some random noise, it displays ‘Unknown’ encoding. So when using a generic RC that operates in NEC standard the receiving packets are recognised as ‘NEC’. One button press generates one packet as it is shown on the video below.

However, it immediately turned out that it is not the case for the Mini RC. It uses neither of the abovementioned standards, it speaks some dialect of NEC with terrible accent. First packet seems to be in NEC standard but after it one or two more are sent in unknown encoding. And what is even worse, the result varies from one button press to another as it is shown on the video below.

The conclusion that came out of this test. The RC is generally functional so it is not complete waste of money. However, 2 buttons out of seven are fake (‘TV’ and ‘LED’) so obviously you can’t switch on and off any TV. Five remaining buttons send a bunch of codes in one go using several standards for reasons unknown. Also in our tests we were receiving different codes after pushing the same button so in this sense it was behaving rather unreliable. And finally, there are some doubts that the battery is going to last for a reasonable time. Two simple facts speak in support of that because a) battery is not installed in RC when you buy it and b) the LED flashes every time when any button is pressed. All in all, it is not a brick and does some useful things but in our view it is not worth even 3 dollars, sorry. The general rule is still in place – very cheap things work cheap.

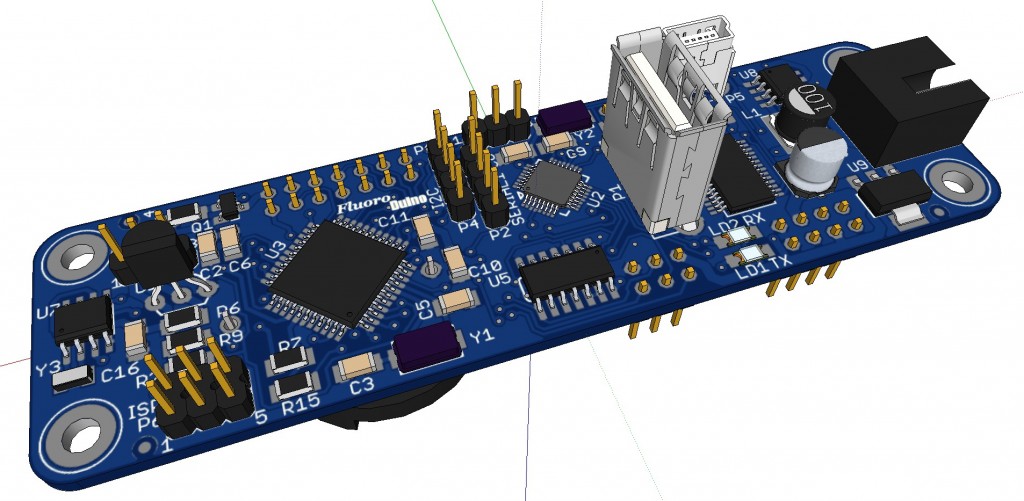

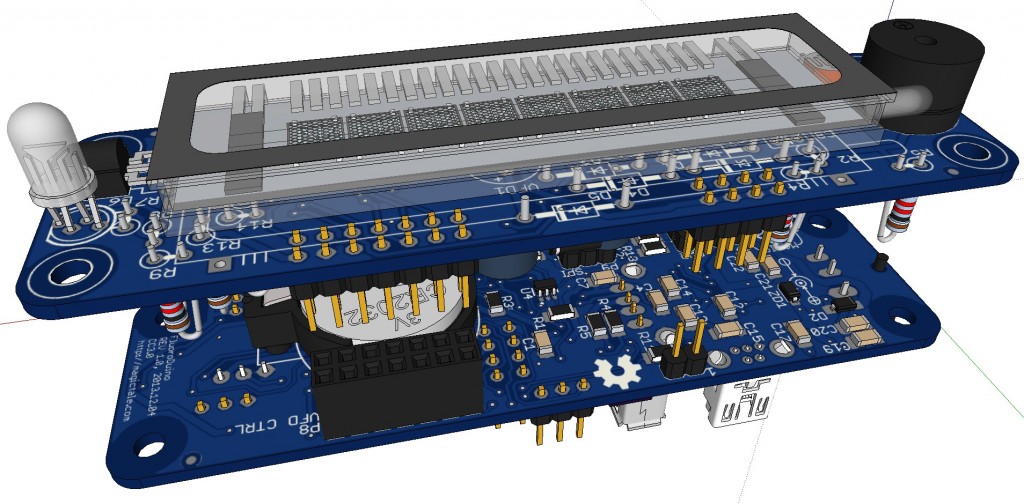

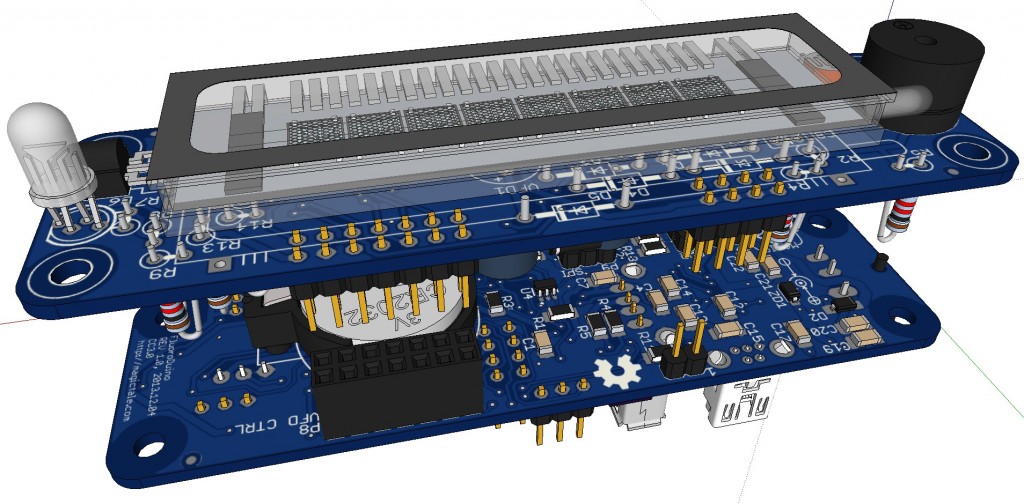

Luminardo was specifically designed to work together with Vacuum Fluorescent Display (VFD) panels such as MVFDPanel 16S8D. One of the most distinctive features of Luminardo is its low profile. The board also shares same dimensions with VFD module so the final product looks very compact and unusual, it could be easily embedded into a car dashboard or something similar. Currently there is only one type of VFD module with more yet to come – all of them will be sharing the same form factor making possible to evolve the project into something like Lego. Luminardo is a flexible solution, it comes with USB client, USB host, I2C, SPI, ISP, 1Wire and Serial interfaces. Having USB host onboard means that the board is easily integrated with huge variety off-the-shelf devices such as USB sticks, USB hard drives, Bluetooth, WiFi and so on. The board also has a connector for PIR sensor, a battery backed up RTC, an embedded temperature sensor with possibility to connect external 1Wire devices. Obviously there is an option to connect extension boards (or shields) building more complex and sophisticated systems. The board can be powered either off unregulated 12V or 5V (USB) interface. There is a way to power it off an alternative source of energy, for instance, solar/lithium battery shield of even something more exotic.

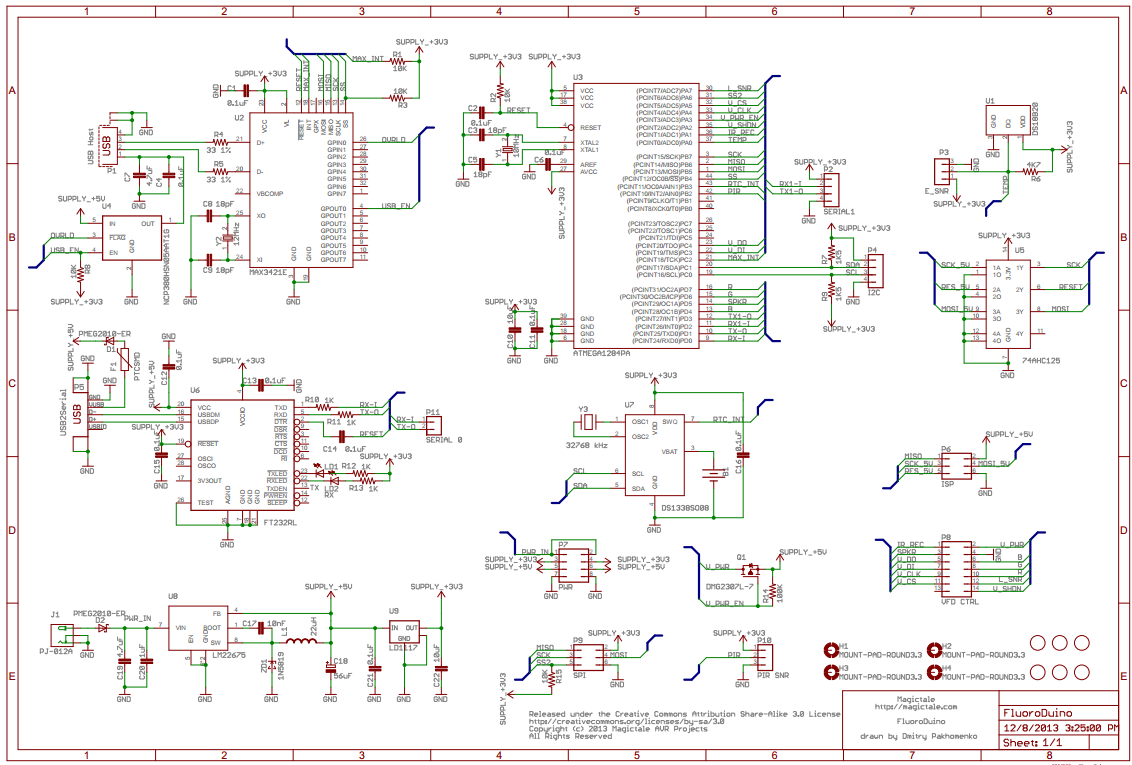

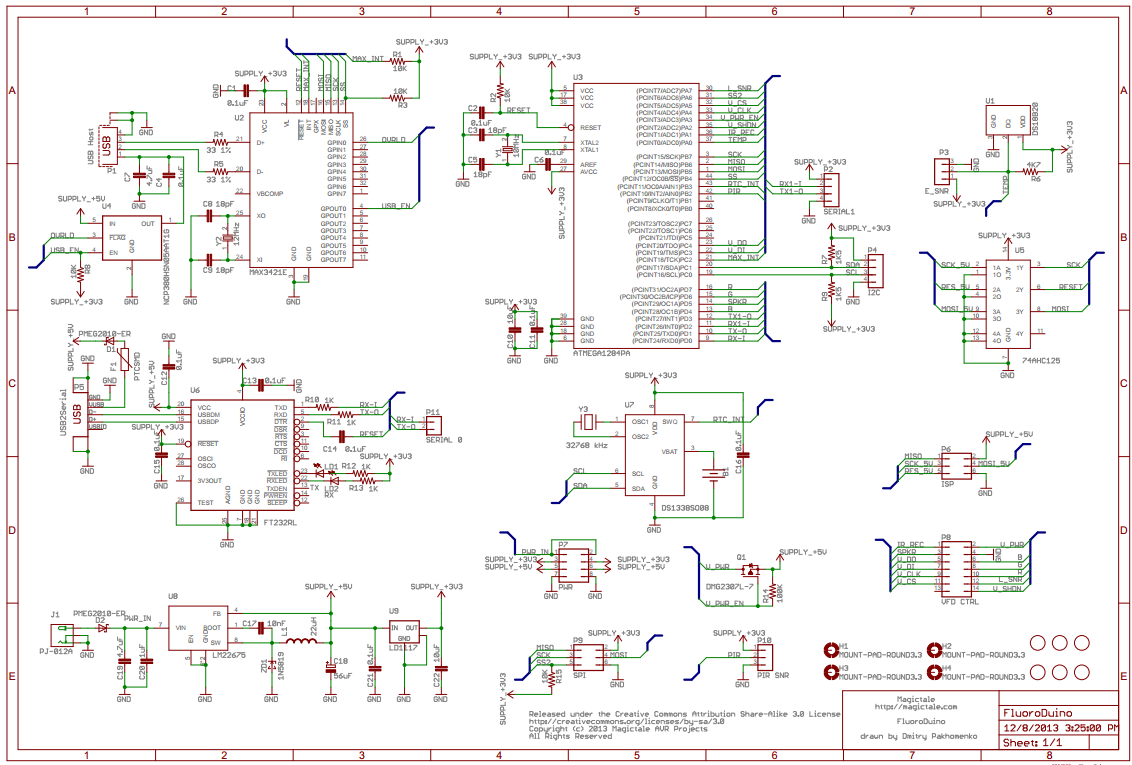

The circuit diagram of the motherboard is given below.

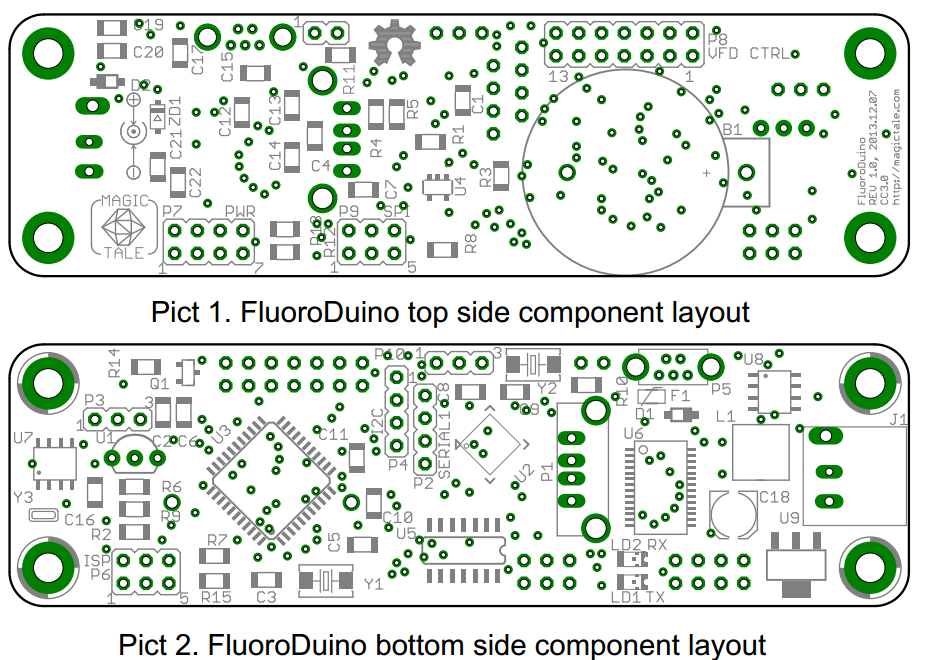

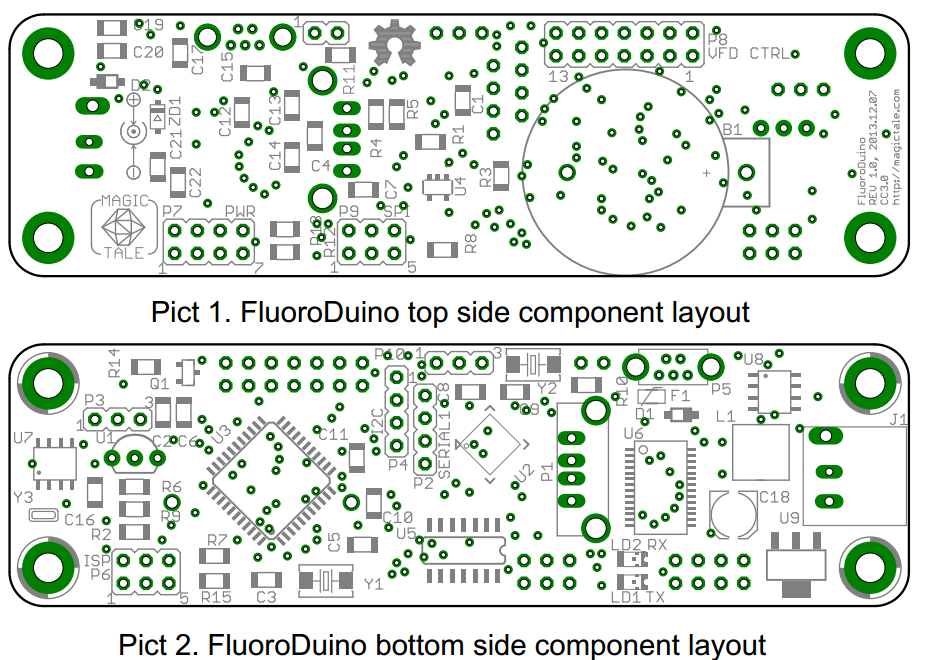

Luminardo Circuit Diagram Rev. 1.0 The PCB layout is done on two layers with dimensions less than 100mm x 27mm which allows to be within limitations of ‘light’ Eagle license and take advantage of 100mm x 50mm PCB manufacturing service from ITead Studio. Component placement for top and bottom sides are given on the pictures below.

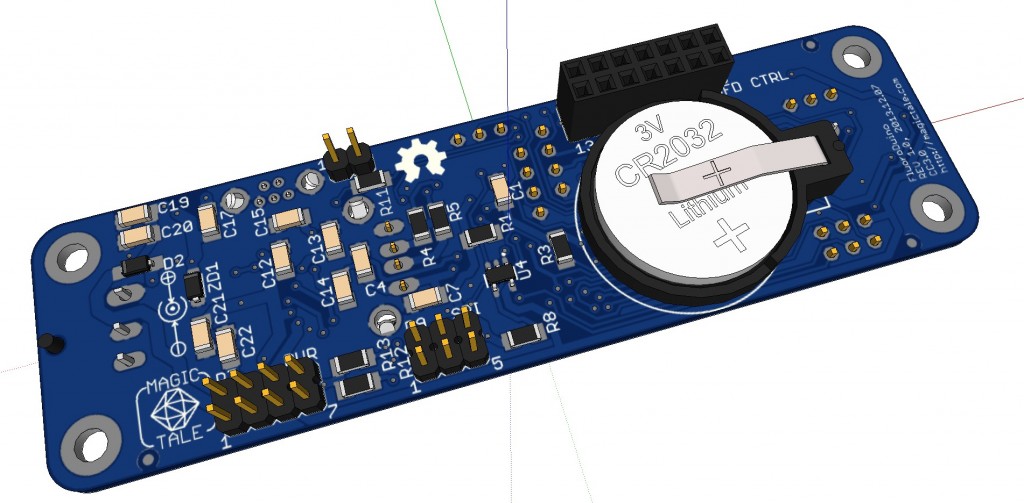

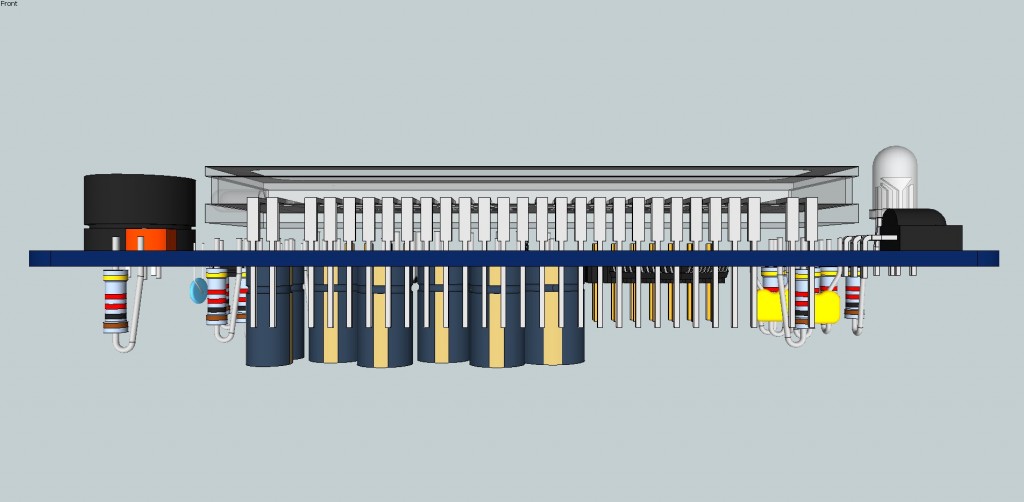

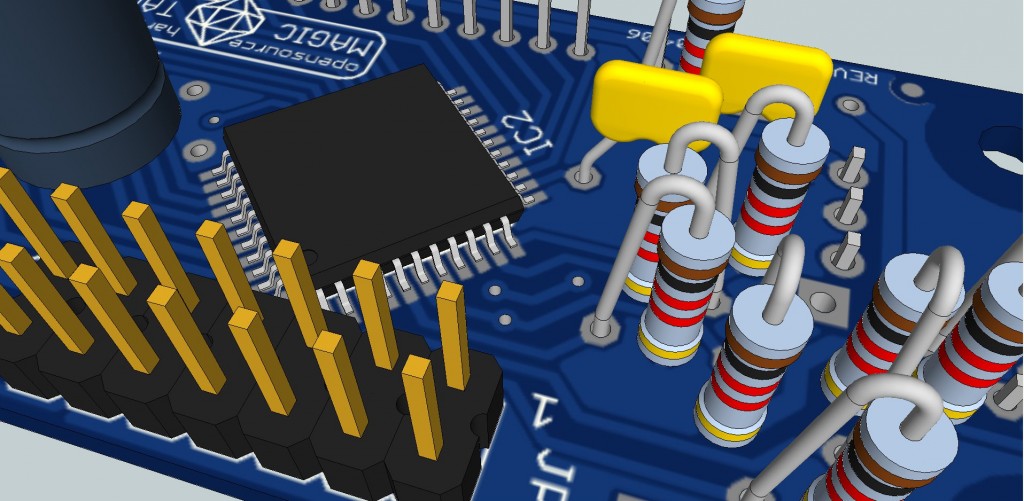

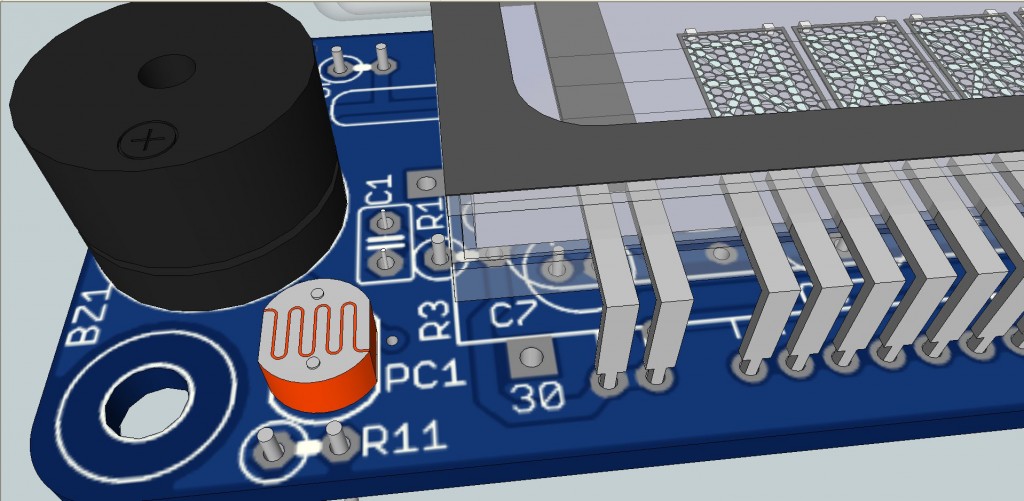

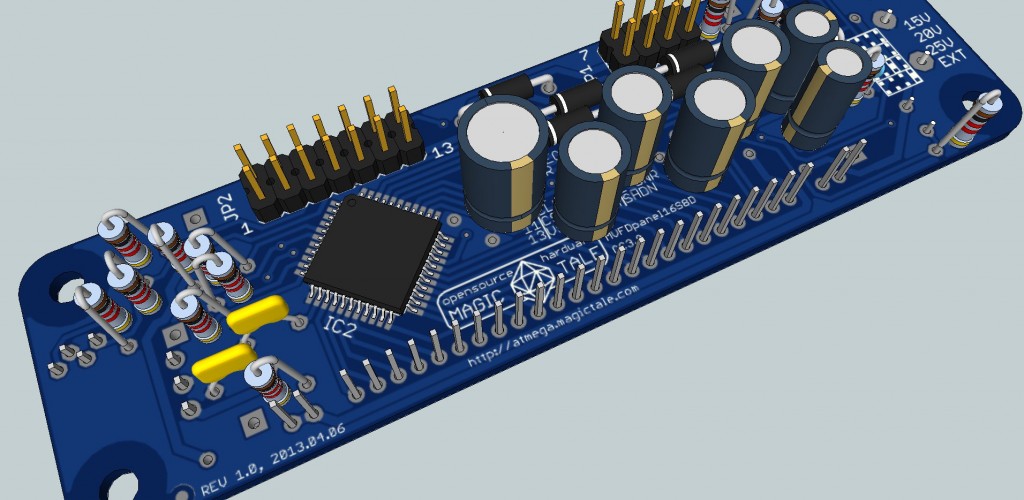

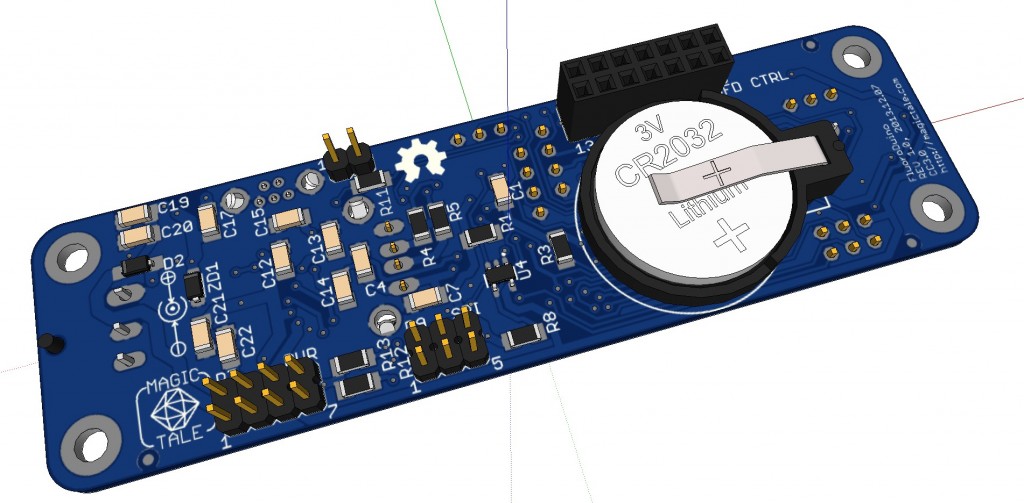

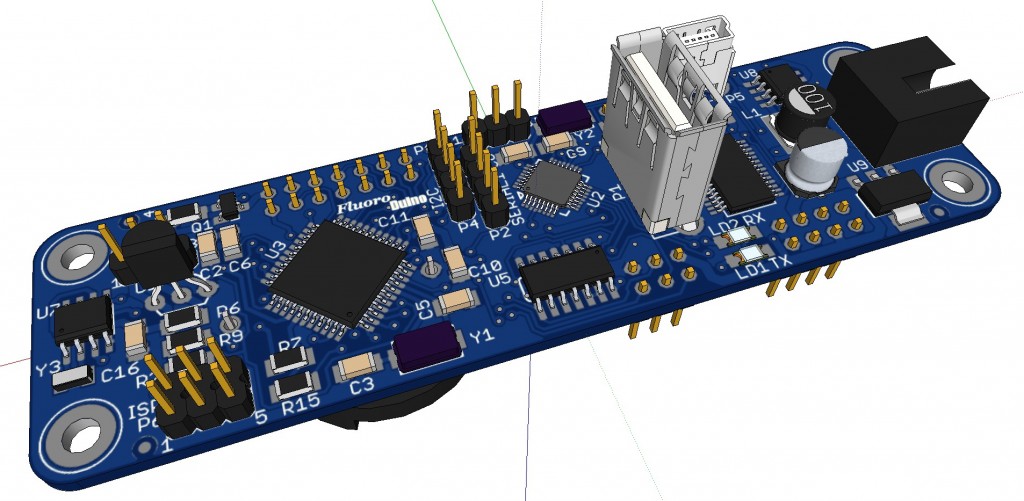

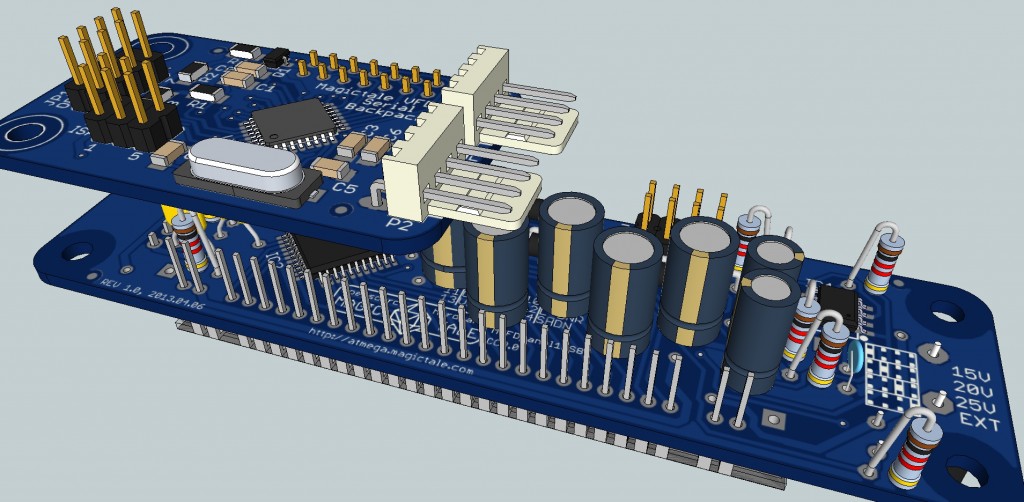

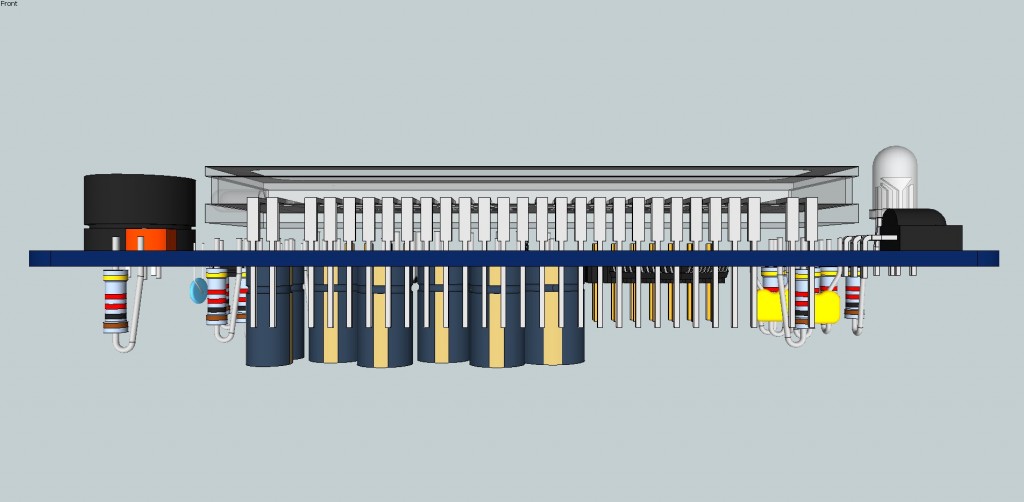

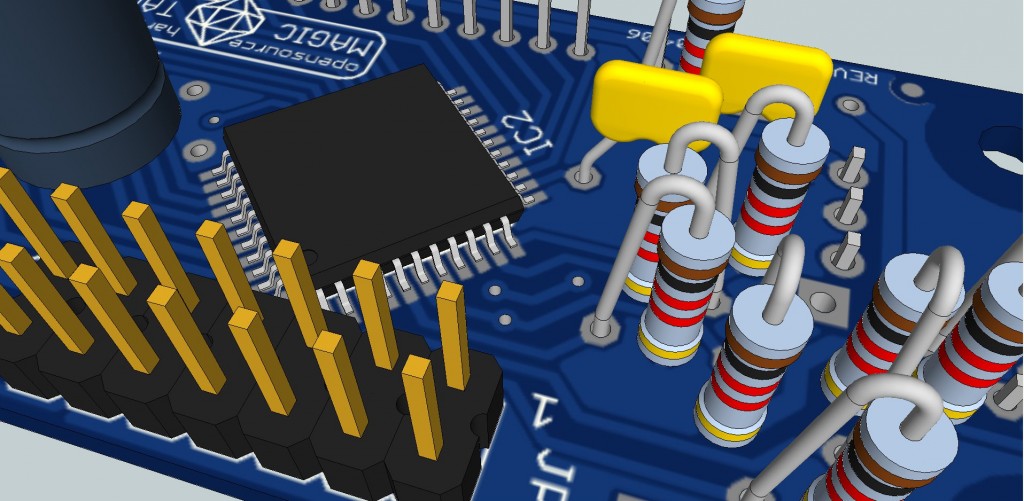

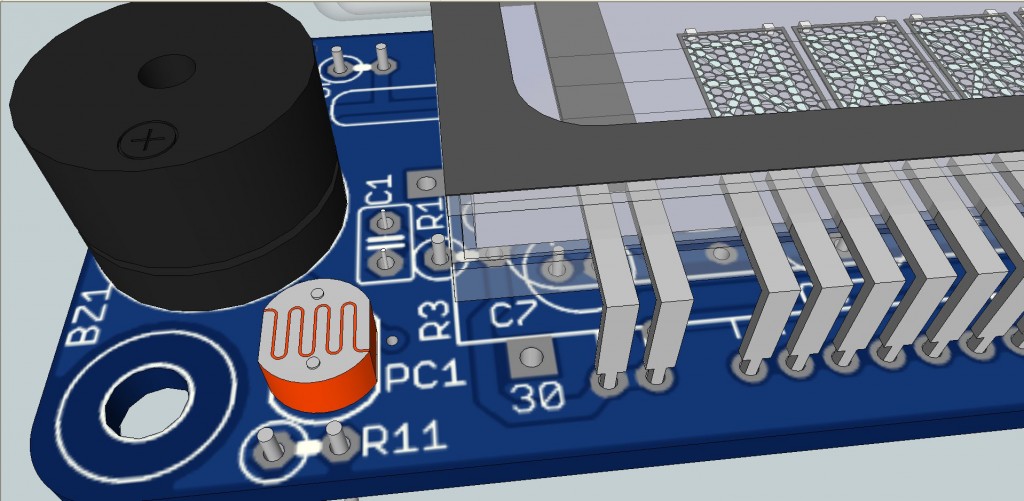

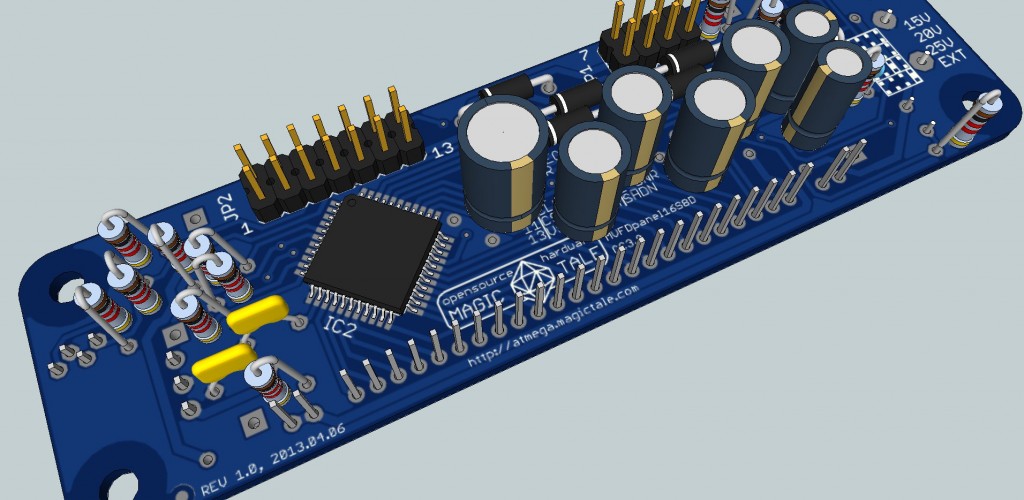

Luminardo Component Layout Rev. 1.0 A 3D model of the PCBA is available in Google 3D Warehouse.

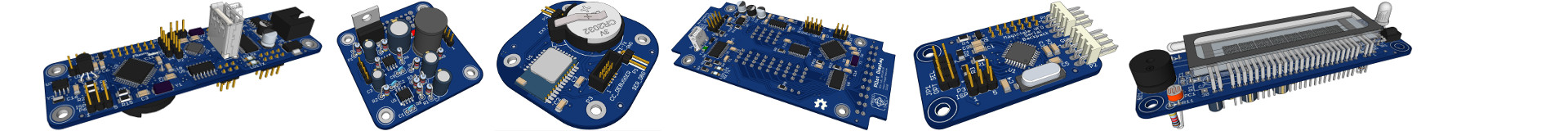

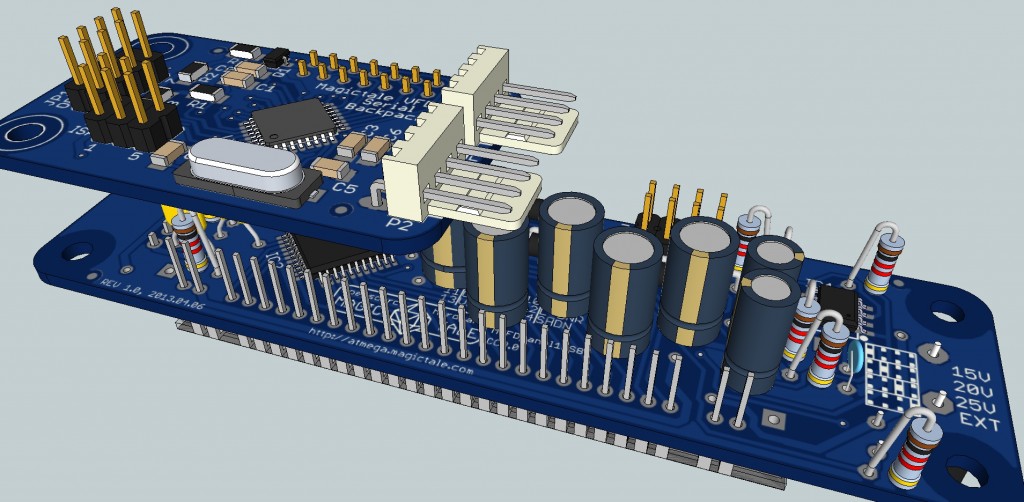

Luminardo PCBA 3DModel Top Side  Luminardo PCBA 3DModel Bottom Side  Luminardo With MVFD 16S8D Panel Downloads:

1. Luminardo Gerber files Rev1.0

2. Luminardo Eagle files Rev1.0

3. Luminardo SketchUp 3D Model Rev1.0

4. Luminardo Component 3D Models

5. Luminardo BOM (Bill Of Materials)

ATMega source code is yet to come – stay tuned.

Note that originally this project was named ‘FluoroDuino’ and later it was renamed to ‘Luminardo’ so please don’t be surprised when you download Rev.1.0 design files – there is still the old name.

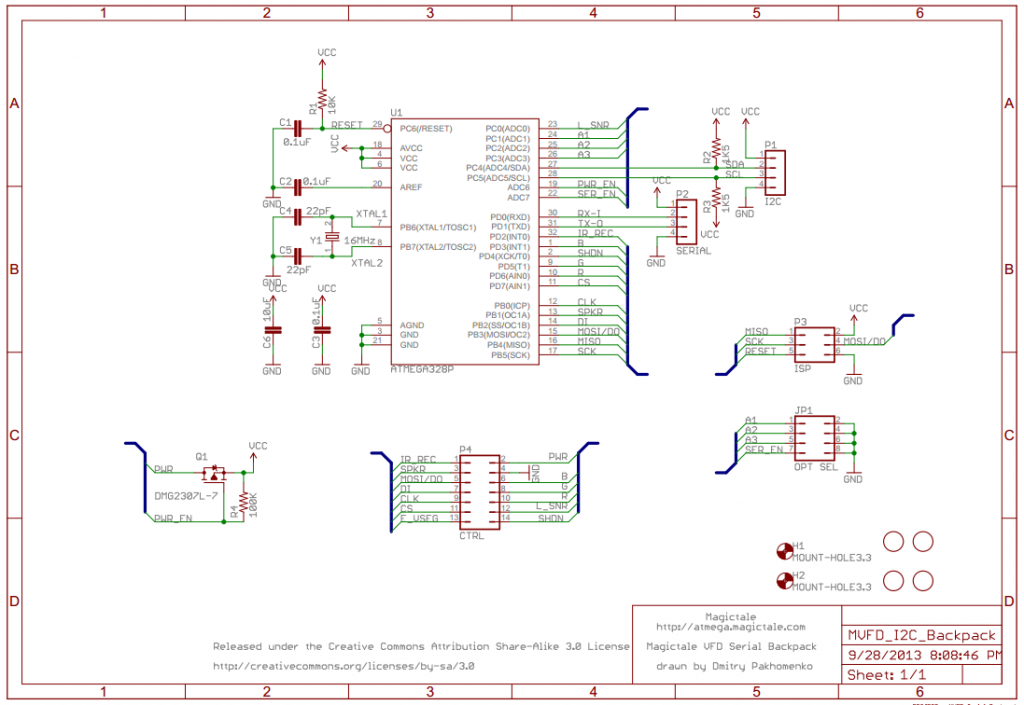

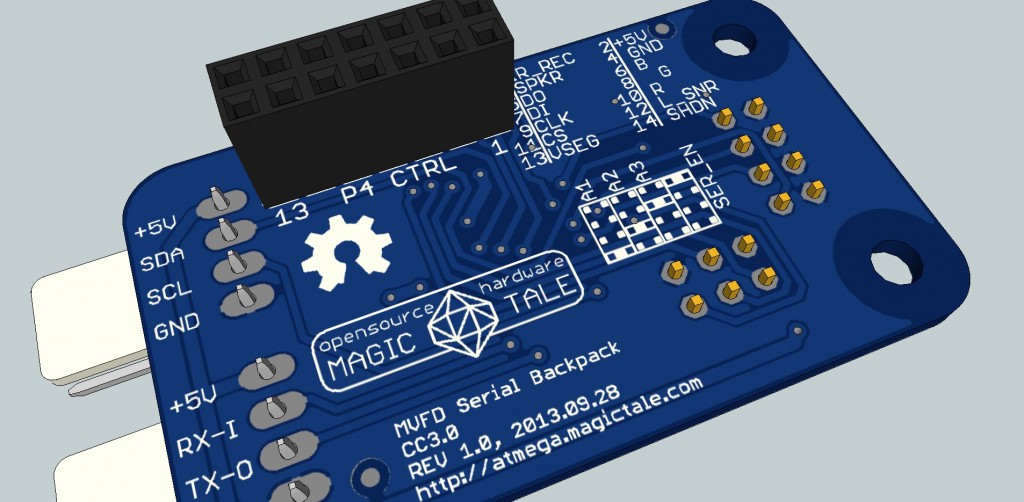

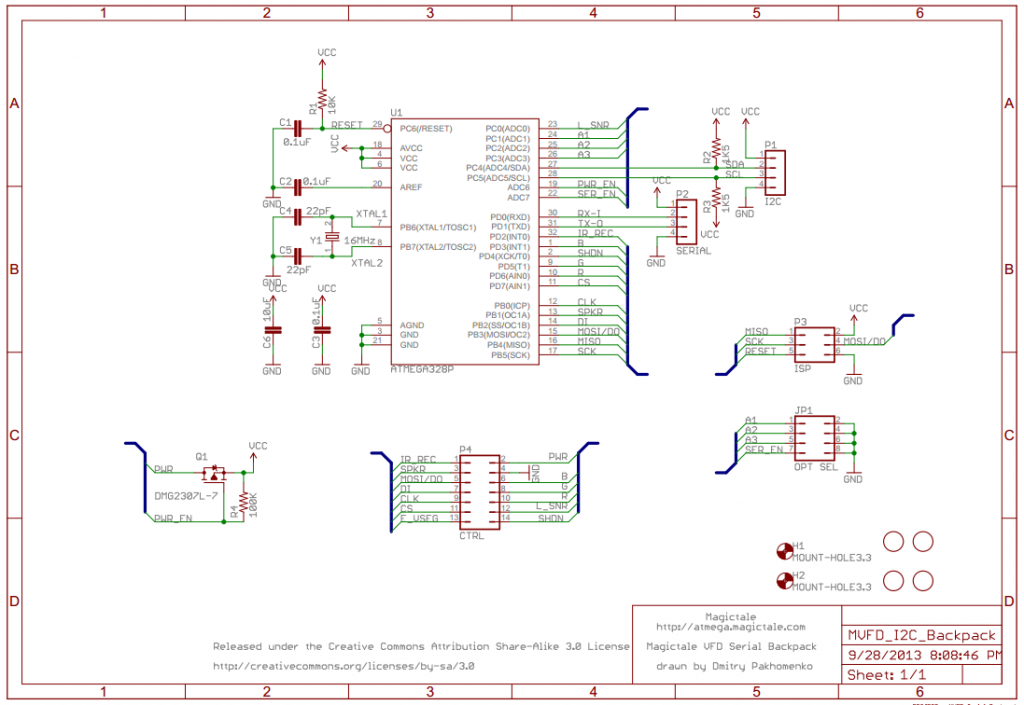

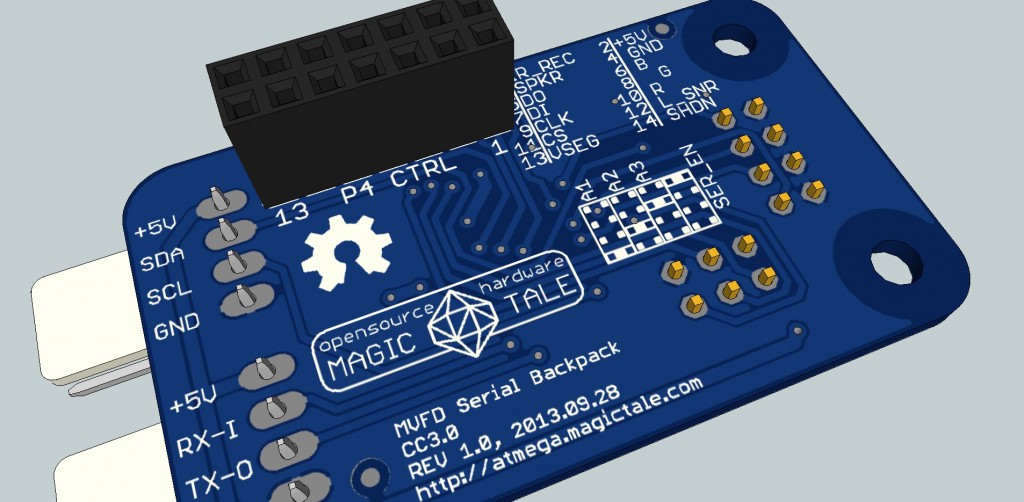

With MVFD Panel requiring substantial amount of pins it becomes really first priority to minimise the number of GPIO and processor’s resources for some projects. That is where MVFD Serial Backpack comes to play. It takes responsibility of communication with VFD panel and conveniently provides either I2C or Serial interface to the main controller. Very useful when the number of available GPIOs or microprocessor resources is limited or when there is a need to build a working prototype with minimum effort. The circuit diagram of the module is given below.

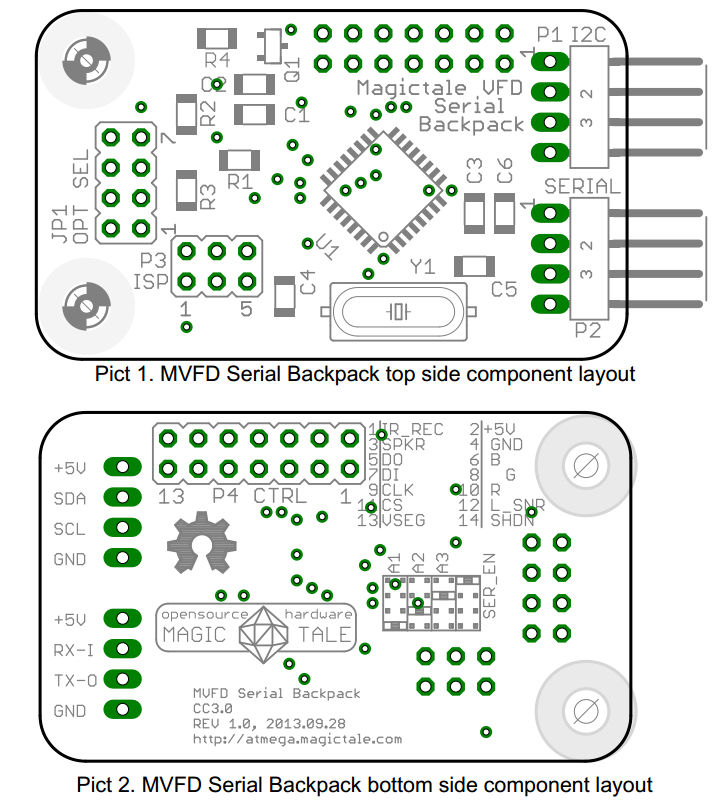

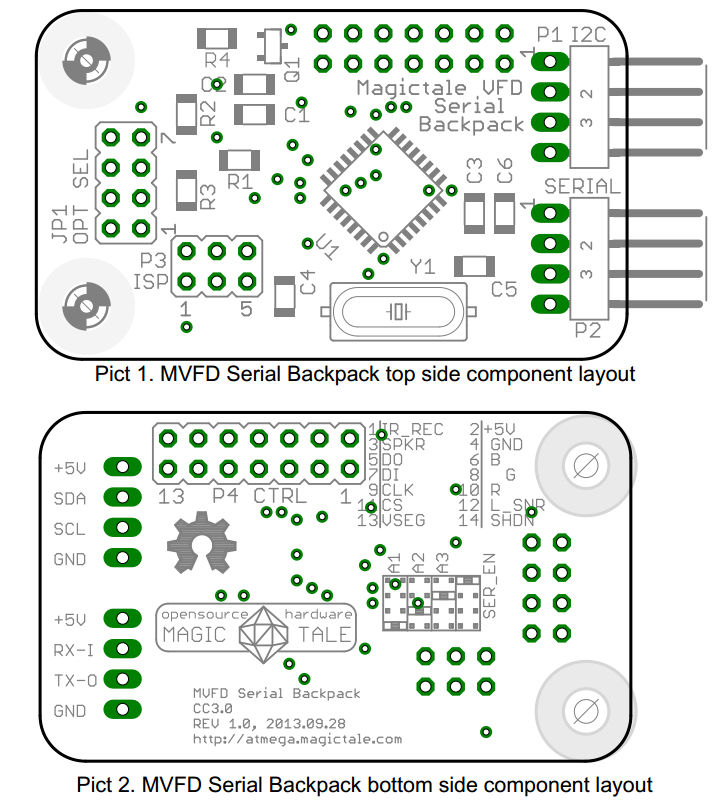

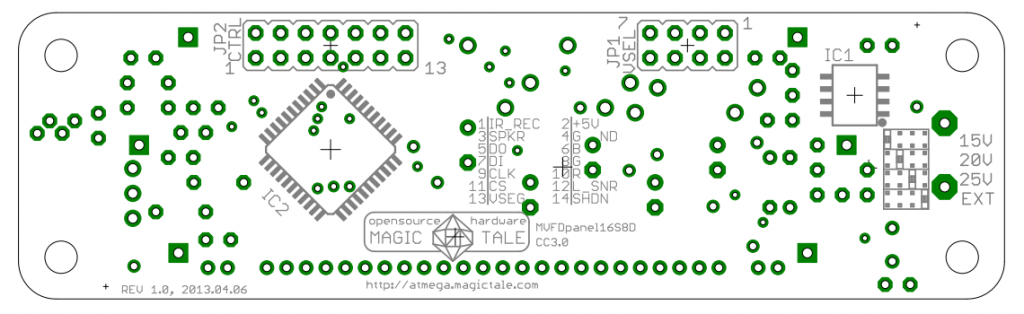

MVFD Serial Backpack CircuitDiagram Rev.1.0 The PCB layout is done on two layers with dimensions less than 50mm x 50mm which allows to be within limitations of ‘light’ Eagle license and take advantage of 50mm x 50mm PCB manufacturing service from ITead Studio. Component placement for top and bottom sides are given on the pictures below.

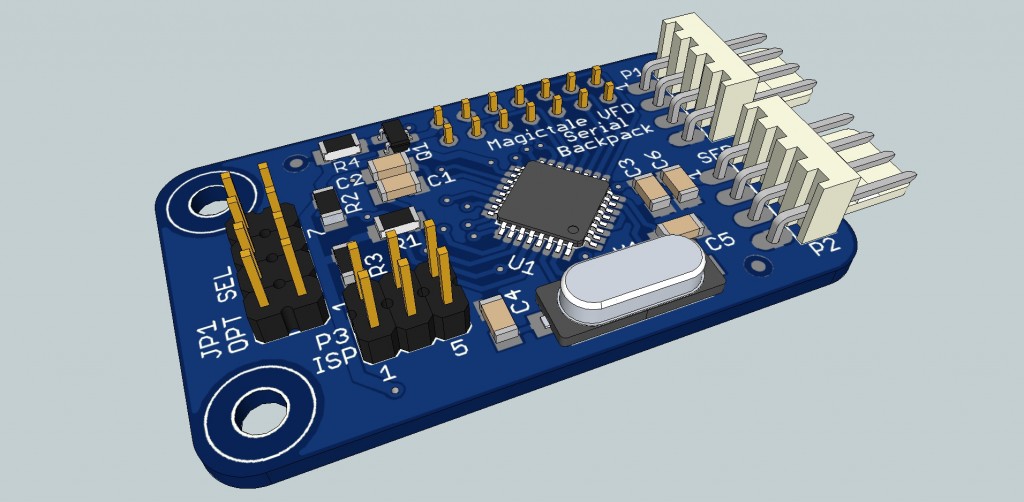

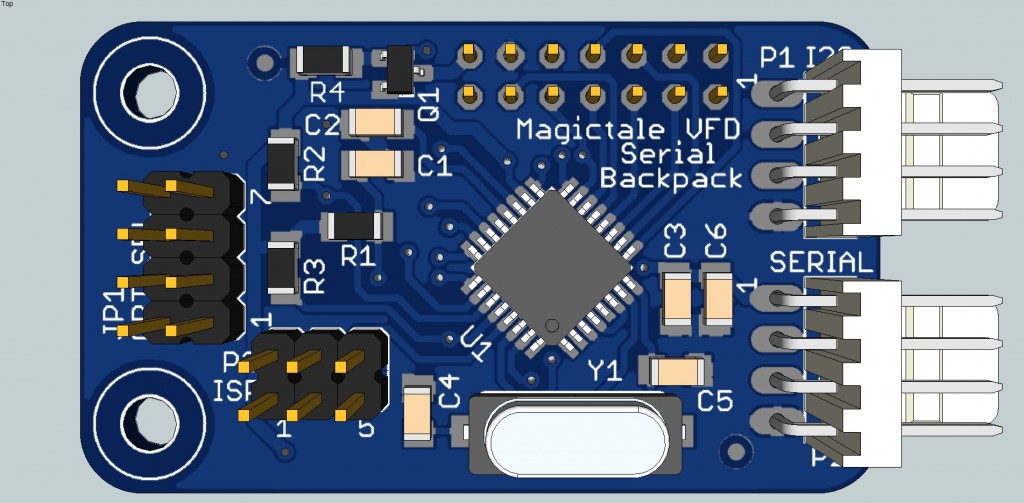

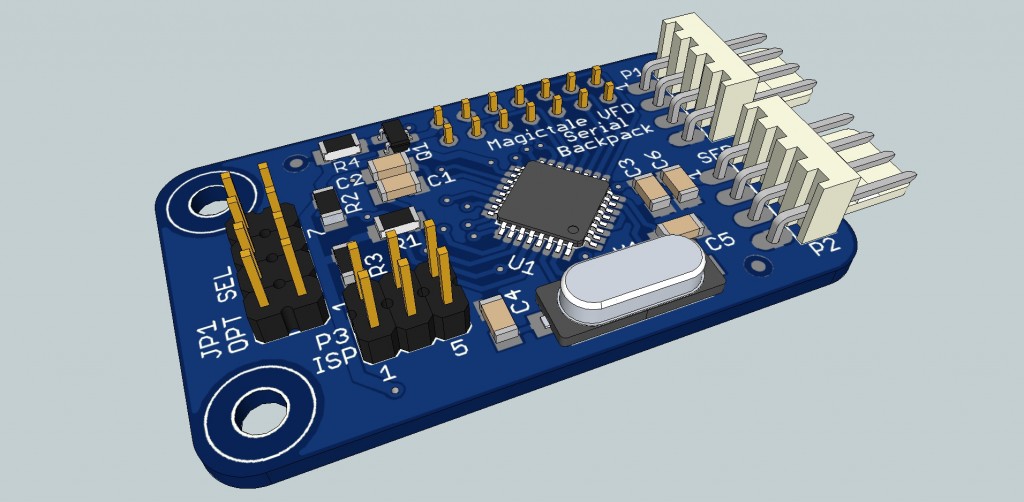

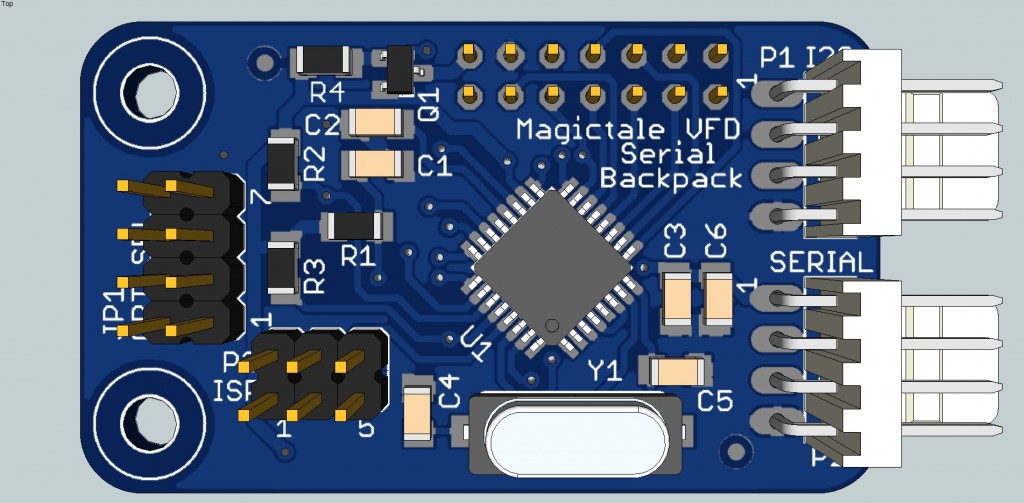

MVFD Serial Backpack PCB Comp Layout Rev.1.0 A 3D model of the PCB is available in Google 3D Warehouse.

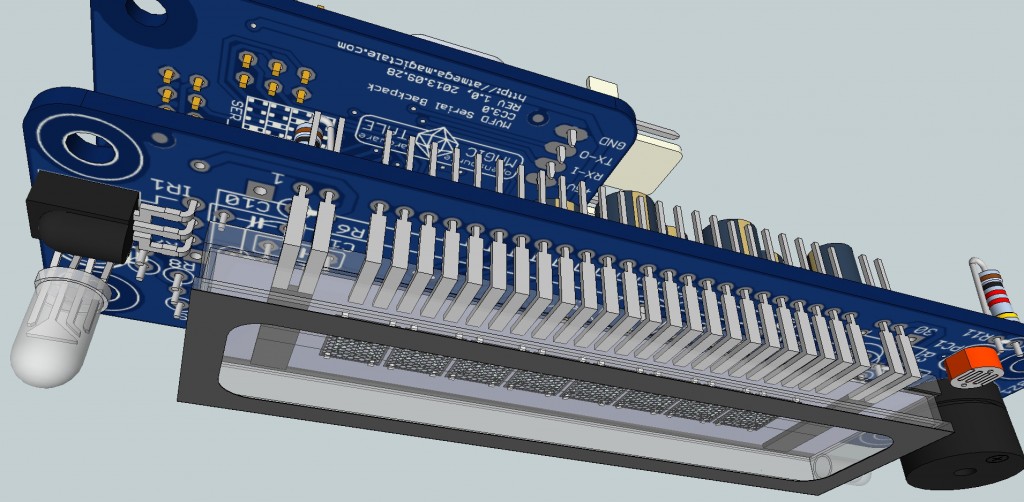

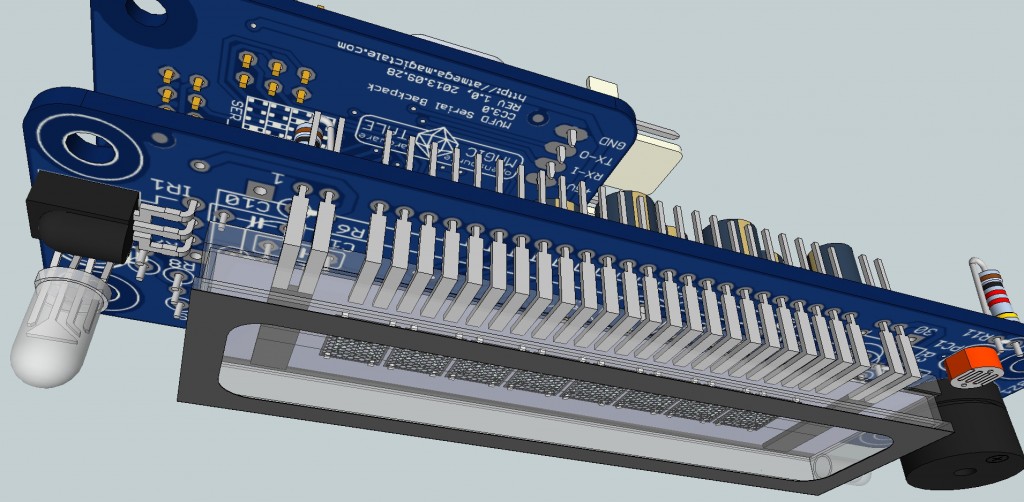

MVFD Serial Backpack 3D Top 2  MVFD Serial Backpack 3D Top  MVFD Serial Backpack 3D Bottom Both MVFD Panel and Serial Backpack fitting together are shown below.

MVFD Panel And Serial Backpack 3D 1  MVFD Panel And Serial Backpack 3D 2 Downloads:

1. MVFD 16S8D Serial Backpack Gerber files Rev1.0

2. MVFD 16S8D Serial Backpack Eagle files Rev1.0

3. MVFD 16S8D Serial Backpack SketchUp 3D Model Rev1.0

4. MVFD 16S8D Serial Backpack 3D Models

ATMega source code is yet to come – stay tuned.

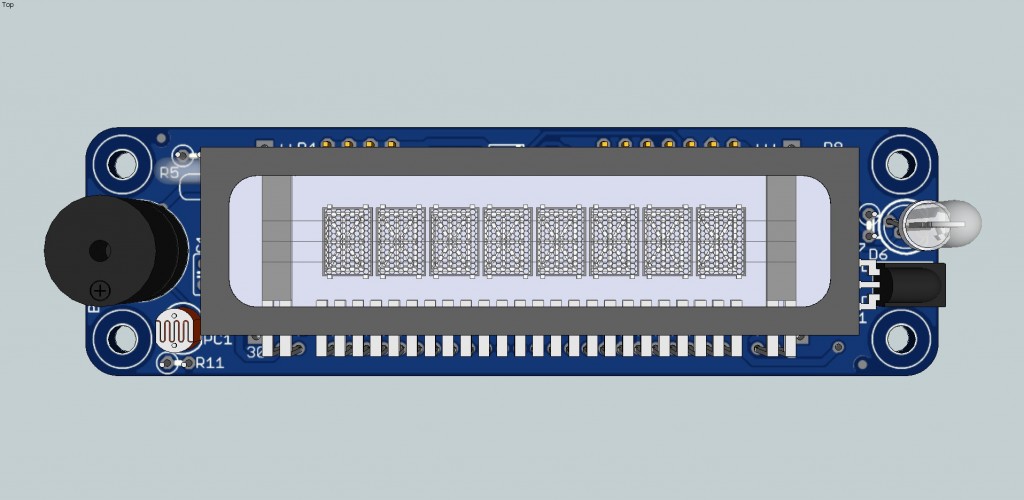

Building a 3D model from PCB design files can bring your project to a totally new level. It comes at a price as it requires extra design time but being properly done it saves a lot of effort and money in the future as it minimises risks by helping to capture issues on early stages of design cycle.

First and most obvious plus of a 3D model is that is allows to estimate dimensions and optimise component layout. This is especially useful when components are soldered on both sides of PCB and some components are located in close proximity to each other or even overlap if, for example, some passive elements are destined to be under a bigger one such as LCD/VFD display, sensor, heatsink or something else. Secondly, if a project comprises of a several PCBs it becomes even more important that there is no interference between them. Also 3D view helps to pick up such things as drill hole sizes as it becomes clear whether a pin fits in a hole or not. It is also useful to access the overall look of the future assembly before it is physically assembled and experiment with such things as PCB mask color for instance to make right choice. 3D design of PCBA is one step closer towards subsequent enclosure design, be it laser cut acrylic panels or a model for 3D printing. And finally, design files accompanied by a 3D model make a project to look very professional and significantly simplifying following creation of project’s documentation.

There is absolutely amazing plugin called EagleUp that makes a bridge between Eagle CAD and SketchUp. The plugin allows to automate export of PCB design files into 3D world but of course not everything can be automated – there is still need in 3D footprints that have to be created first. Some 3D footprints are already created by someone else and could be found at Google 3D Warehouse but be prepared that not all of them exist and you have to design a few models for your project by yourself. The whole process is thoroughly described here and here so we recommend to refer to these resources for more information. From our personal experience the only strange part that we found in EagleUp was a necessity to design footprints using meters instead of millimeters resulting the models to be 1000 times bigger. But this issue is easily rectified by scaling down fully modeled PCBA back to millimeters.

The result of our effort is given below as a model in Google 3D Warehouse.

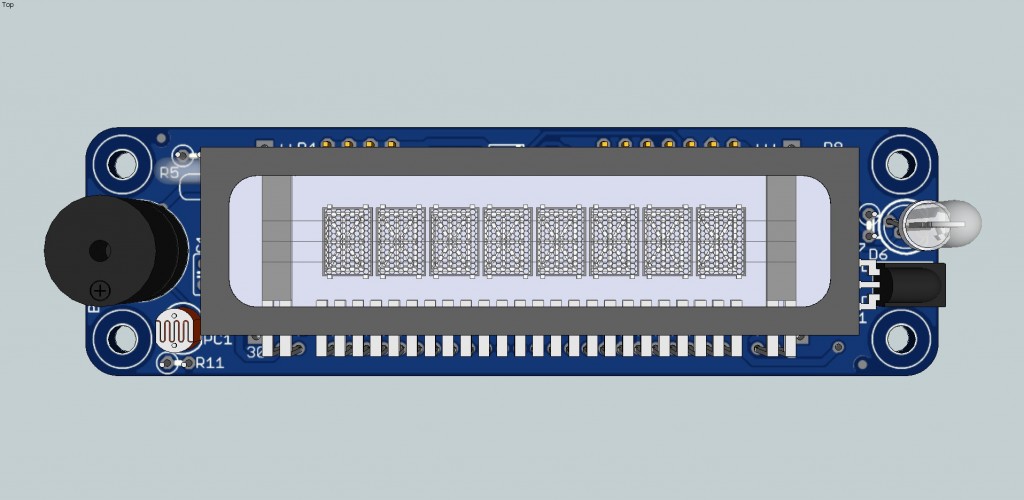

The pictures below show the model at different view angles in SketchUp.

MVFDPanel 16S8D 3D Pic.#01  MVFDPanel 16S8D 3D Pic.#01  MVFDPanel 16S8D 3D Pic.#03  MVFDPanel 16S8D 3D Pic.#03  MVFDPanel 16S8D 3D Pic.#05  MVFDPanel 16S8D 3D Pic.#06 Downloads:

1. MVFDPanel 16S8D SketchUp 3D Model Rev1.0

2. MVFDPanel 16S8D SketchUp 3D Footprint Models

Mastech HY5003 Bench Power Supply is a good choice for a home lab. It is inexpensive, noiseless, not very space demanding, easy to use. Features include 50VDC@3A, 150W, constant voltage/constant current/restricted current modes, fine and coarse voltage and current adjustment. Just enough for most cases of amateur electronics designer activities. And if you are lucky to have a unit compliant with your mains power voltage then you don’t need to read this article any further. This post is for those who for some reasons have an appliance rated for 110V while your mains voltage is 220V and the other way around. Why would you choose a power supply which is incompatible with your mains voltage? – an attentive reader may ask. Well, life is more difficult that we tend to think about it. For instance, we were amongst those unlucky people just because we were not in a position to choose – the power supply was shipped to us from the USA as a prize being won at Hack It 2012 Contest. Upon its arrival it has been discovered that it was simply not rated for Australian standards.

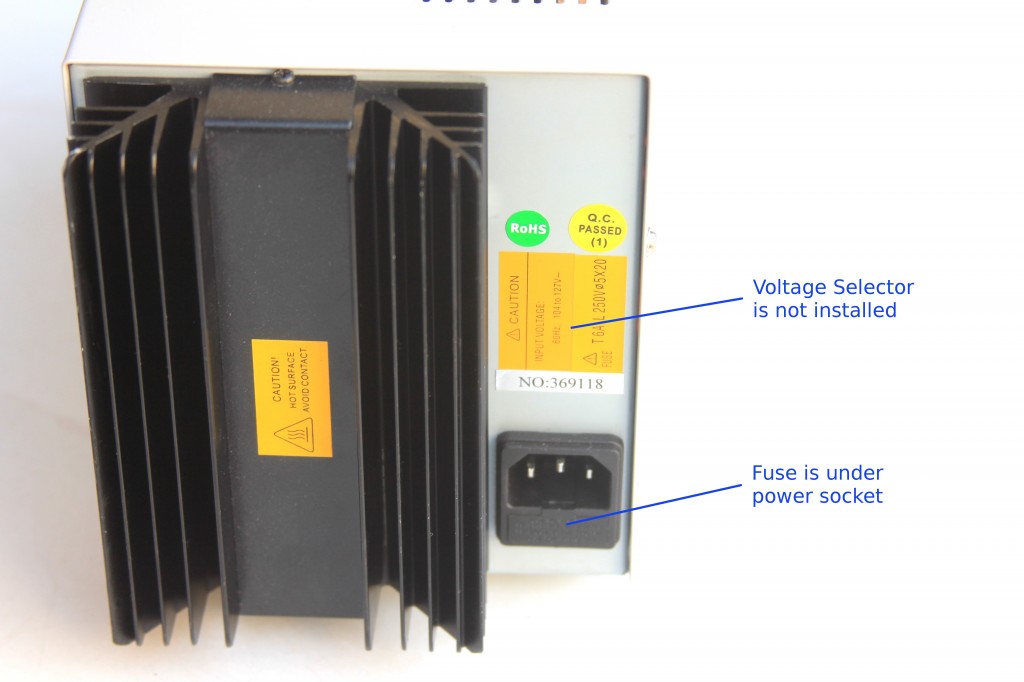

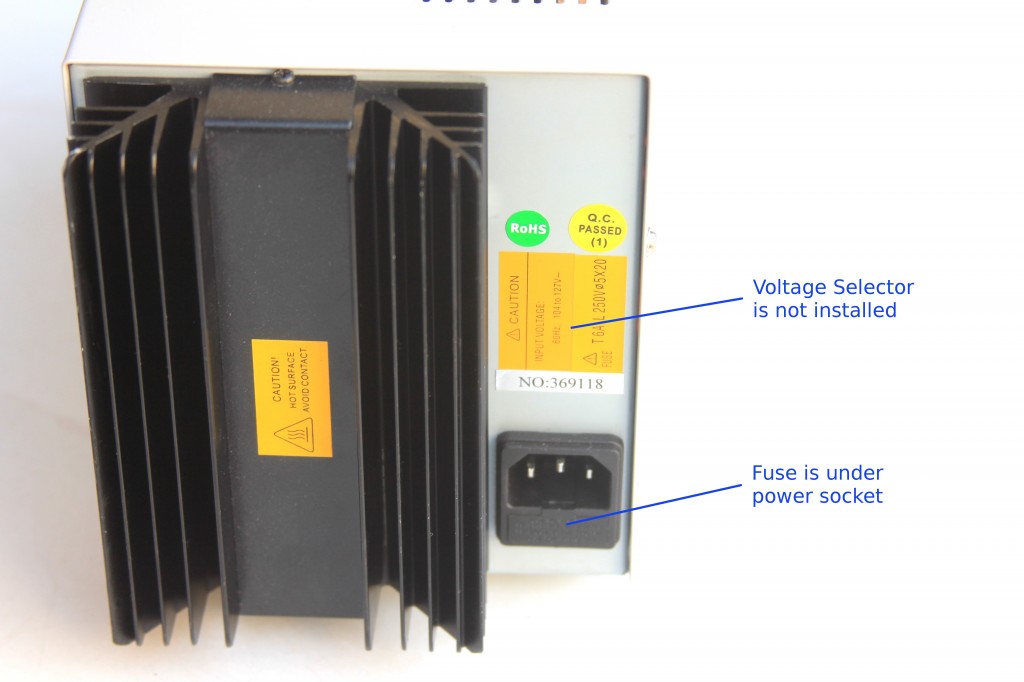

HY5003 Bench Power Supply Assembled If you still haven’t tried to connect your power supply to mains power, please don’t do this just yet – you will blow up the fuse! But if you already did, don’t worry. It is just a fuse, it is hidden just behind the black power socket as shown on the picture below. Just buy a replacement from any electronics store like Jaycar and your power supply is ready for further experiments. Looking at the rear panel it becomes obvious that HY5003 has actually a place for voltage switch. But thrifty Chinese manufacturer opted not to install it sticking a yellow label instead and bringing down the costs even more. Okay, there is nothing more we can do with the appliance without disassembling it so let’s proceed to the next step.

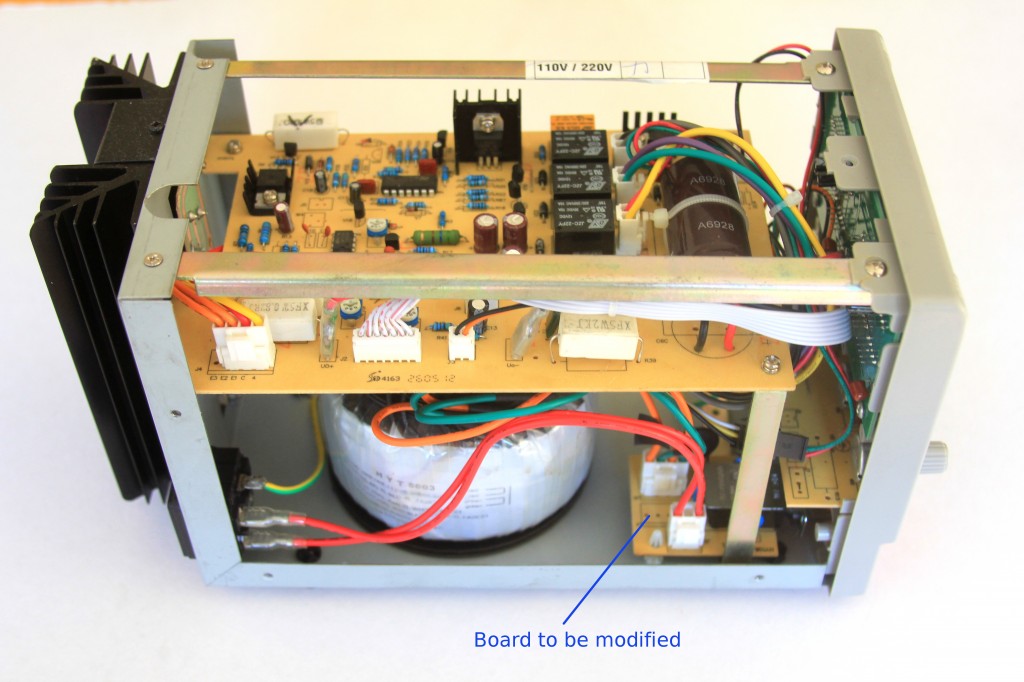

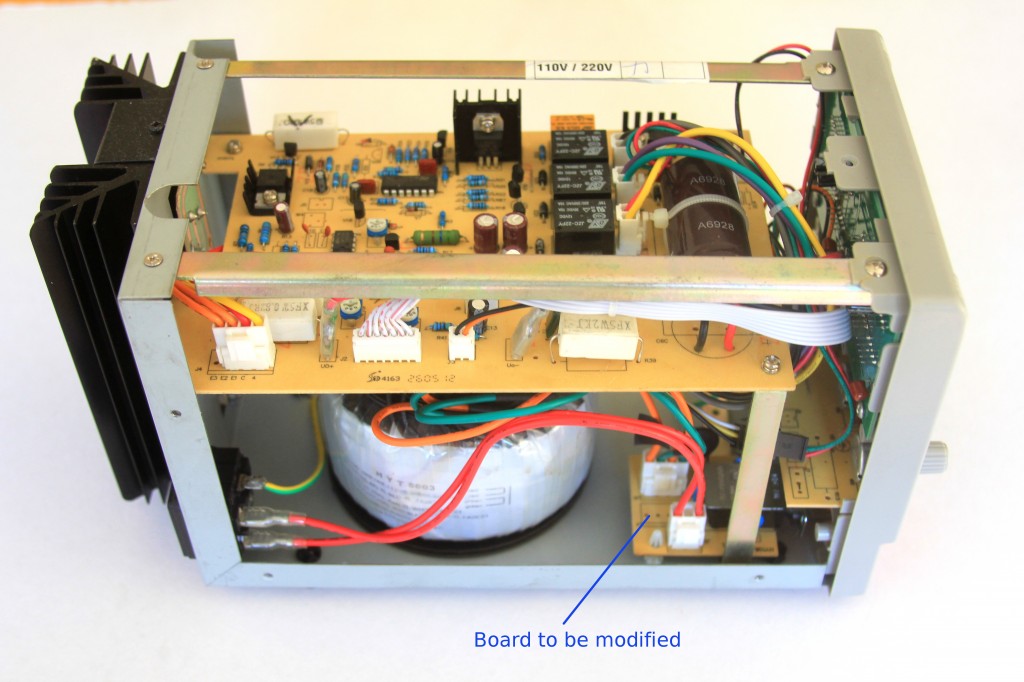

HY5003 Bench Power Supply Rear View Remove the screws and metallic housing (don’t forget to disconnect the appliance from mains power before you start disassembling it!). You should see something similar to what is shown on the picture below. Although there could be some insignificant modifications in construction, in general they all should look alike.

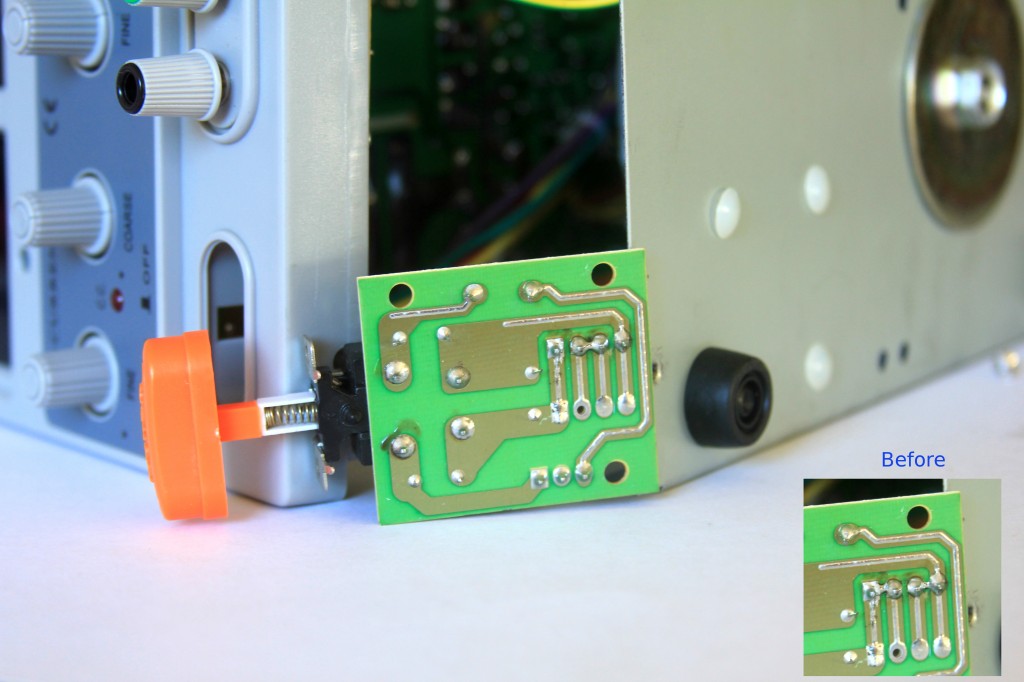

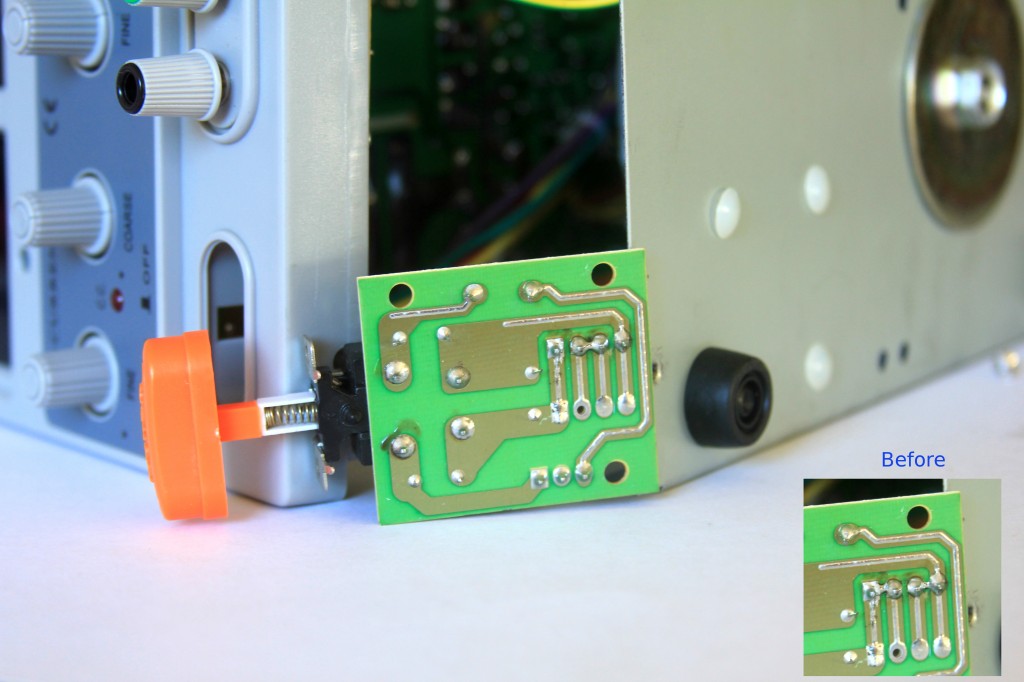

HY5003 Bench Power Supply Board To Be Modified Remove two solder joints as it is shown on ‘before’ overlay on the picture below. Use multimeter to make sure that there is no electrical connection. Then solder together two contact pads in the top middle. This will essentially connect two primary coil sections in series rather than in parallel. Make sure that you haven’t shorted accidently anything else.

HY5003 Bench Power Supply Modification Assemble your appliance. The bench power supply is rated for 220V AC now.

Inspired by the success of VFD MagiClock a decision to make something similar but out of new parts was made. To be fair, despite its appealing look the original clock was assembled using scrapped parts making it really difficult to replicate. In addition to that, rather substantial dimensions and necessity to have cumbersome power supply were amongst the reasons that stimulated us to design something better. New VFD panel would need to address the following criteria:

a) Single (preferably 5V) power supply with filament and high segment/grid voltages being generated internally;

b) Dedicated VFD controller to offload main host controller from resource consuming display refreshing duties and simplify communication interface between display and main controller;

c) Low power mode when display is not used;

d) Compact dimensions;

In addition to this, it would be nice to have the following useful features:

a) Integrated photocell for brightness adjustments;

b) Integrated buzzer;

c) Integrated IR receiver for remote control;

d) Integrated RGB LED;

e) Opensource library written in embedded C++ with Arduino as a primary target platform;

f) When possible use through-hole components rather than surface mounted which would imply less demanding soldering skills if VDF panel is distributed as a kit;

g) Design circuit diagram and PCB layout in CadSoft Eagle which is extremely popular amongst hobbists and electronics engineers;

With filament and high segment/grid voltages being generated internally typical solution includes a transformer which usually a big contributor to dimensions, mass and overall costs. To overcome those obstacles a single chip VFD filament driver has been envisaged. Generated AC for filament would be used to generate high segment/grid DC by means of 5 stage voltage multiplier. A multiplier does not have costly components as it essentially comprises of diodes and capacitors. At that moment the most suitable solution looked feasible with application of LM9022 VFD filament driver. The chip had ‘shutdown’ input effectively cutting down power consumption when VFD was not used making battery power solution possibly.

A dedicated VFD controller/driver significantly simplifies communication with host controller and reduces requirements to it in terms of performance and number of available GPIOs. Display refresh occurs in a timely manner eliminating unwanted flickering and ghost effects. The VFD driver also has 8 steps dimmer circuit for brightness adjustment and high voltage outputs allowing to drive VFD segments and grids directly. A good candidate for our purposes would be HT16515 VFD driver that is widely used in DVD players.

A VFD panel with such characteristics would be extremely simple and easy for integration with embedded host controllers from electrical, mechanical and software points of view.

Integrated photocell, buzzer, RGB LED and IR receiver would enhance the range of potential applications as they usually ‘must have’ features for almost any microcontroller based DIY thing. Despite that fact that the VFD controller chip is capable of driving up to 4 LEDs we wouldn’t connect RGB LED to it, instead, its pins would be externally accessible for host controller giving the freedom of using PWM and therefore resulting in virtually endless number of colors.

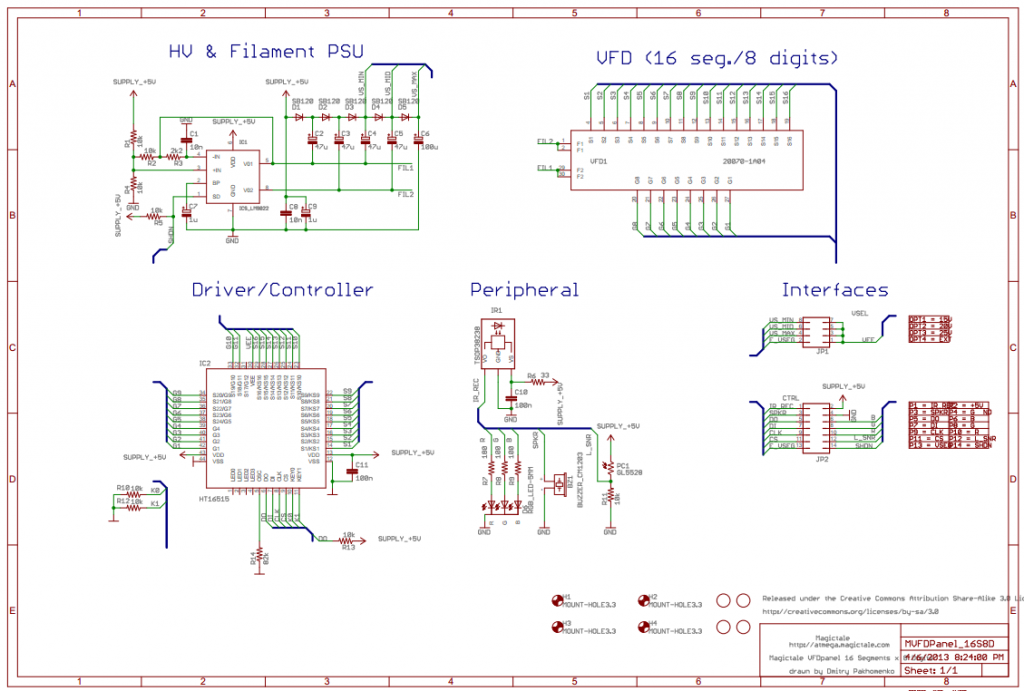

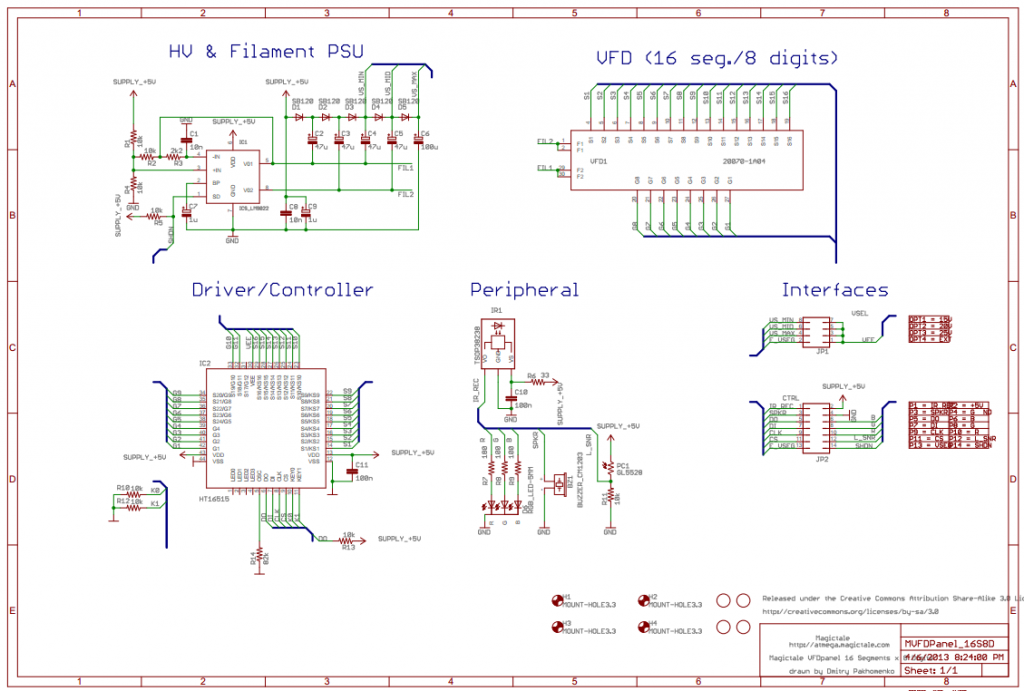

As a result of designing effort the following circuit diagram for the initial revision has been created:

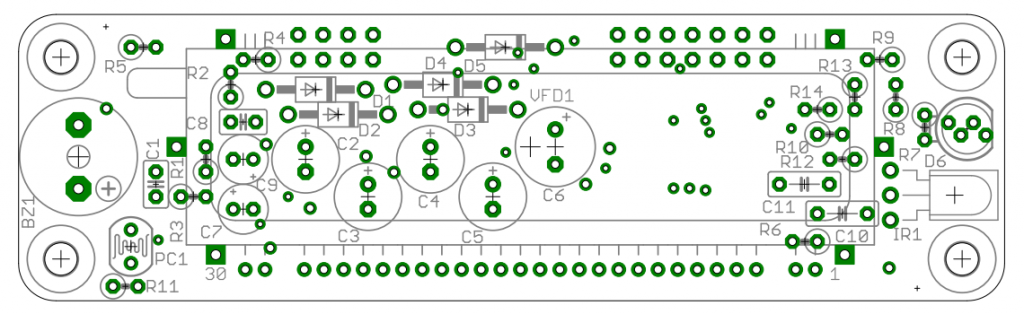

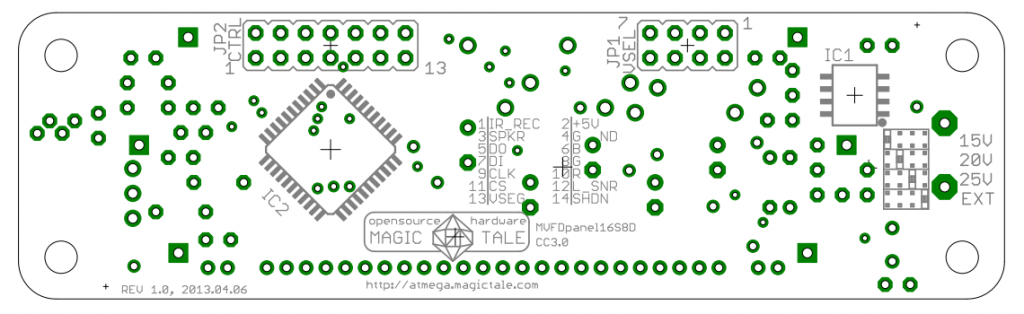

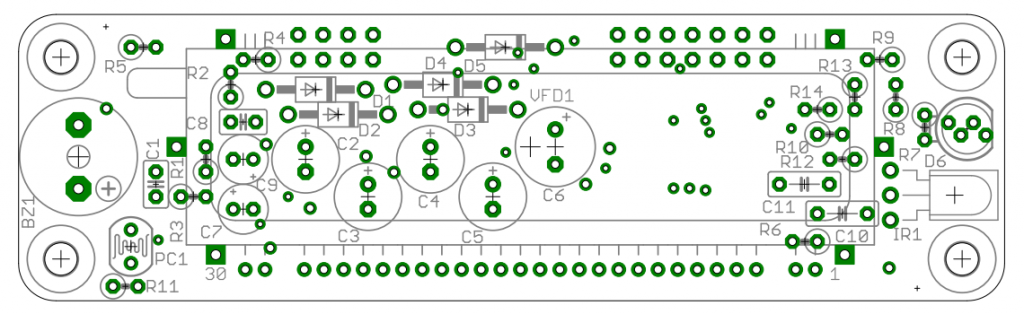

MVFD Panel 16S8D Circut Diagram Rev.1.0 The PCB layout was done on two layers with dimensions 100mm x 29mm which allows to be within limitations of ‘light’ Eagle license and take advantage of 100mm x 50mm PCB manufacturing service from ITead Studio. Component placement for top and bottom sides are given on the pictures below.

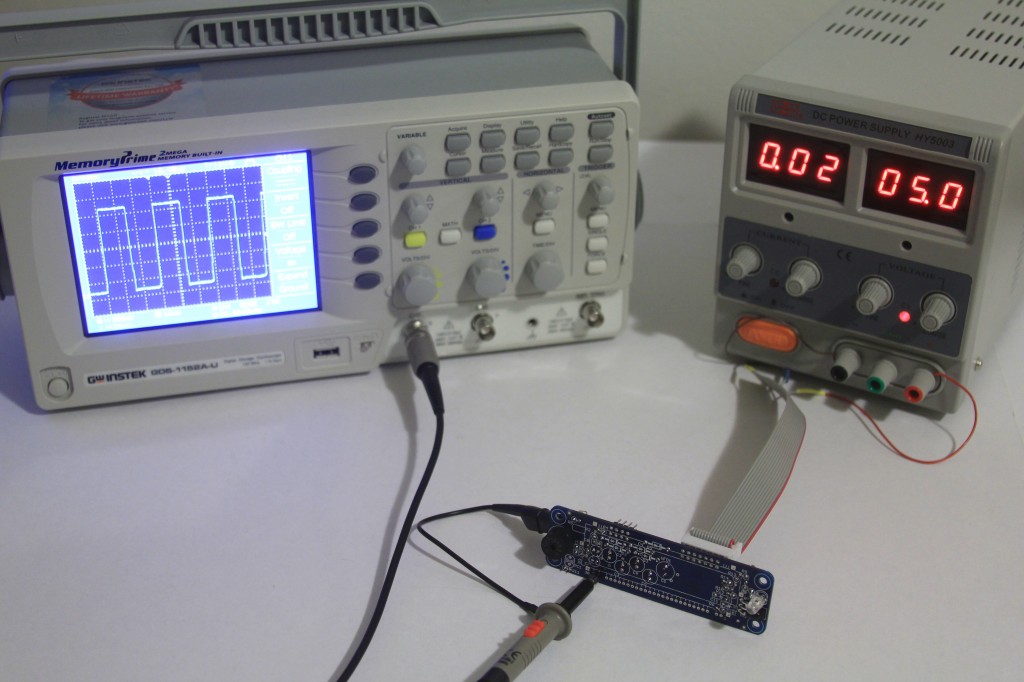

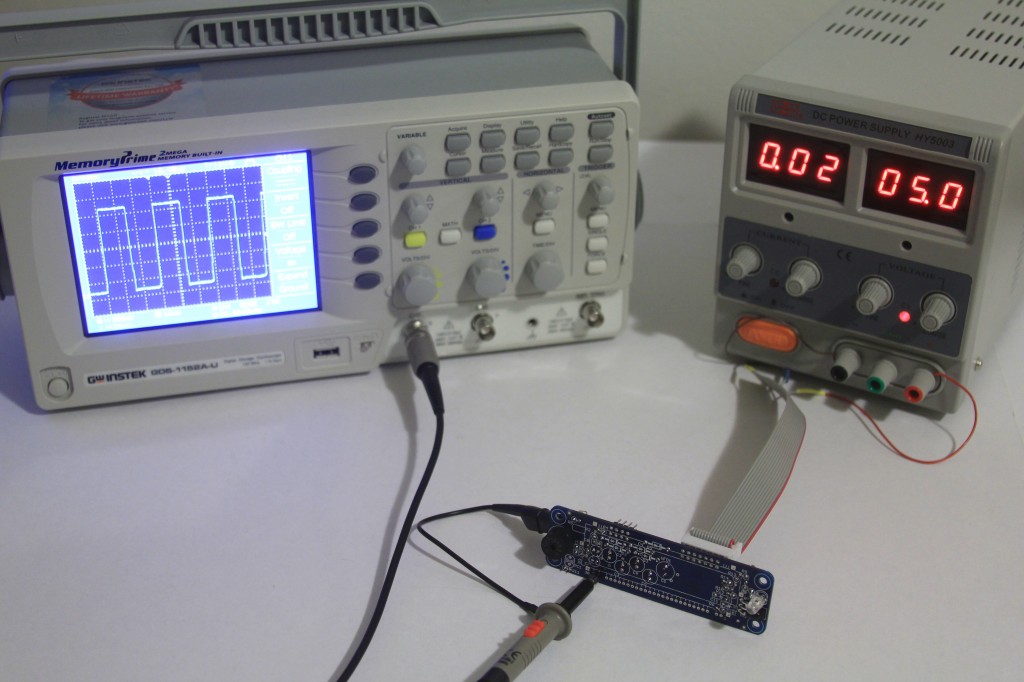

MVFDPane 16S8D PCB Rev.1.0 Comp Top  MVFD Panel 16S8D PCB Rev.1.0 Comp Bottom Everything up to this point looked bright. Up to the moment when the newly manufactured PCBs have been finally delivered. Then we discovered that LM9022 filament driver… became obsolete a few weeks ago! The chips immediately vanished from the stocks of well-established electronic suppliers but appeared on ebay and alibaba, regrettably, with the price doubled. We didn’t have any choice so we bought the chips from ebay supplier, populated PCBs with them a few more components and hooked up a CRO. AC filament voltage was the first sign of life of the VFD panel, as it is seen on the picture below.

Semi-assembled MVFD Panel 16S8D CRO Hooked Up Then there was also a problem with supply of HT16515 VFD controller – it was available in two packages, QFP and LQFP then manufacturer made QFP obsolete as well. Knowing it we designed its PCB landing pattern for LQFP package. The chips were available only at aliexpress service and ‘smart’ Chinese suppliers advertised them as ‘LQFP’ to get rid of old stocks quickly. QFP and LQFP are very similar so it was a real struggle to understand what suppliers actually had in stock. Unfortunately, QFP is slightly bigger so it is a real challenge to solder it on LQFP landing patterns. But it was just about to get even worse. First delivery of 20 HT16515 chips was literally… a scam. All chips were faulty – no even evidence of working internal oscillator when power and a couple of external components are put together. Armed with knowledge that chips in QFP packages are being sold as LQFP we tried to make it extremely clear for for the next picked Chinese supplier, he reassured us a few times that he had LQFPs, we ordered and chips arrived in QFPs again! Likely, this time chips were functional.

But it was just enough to bump into next major issue – no high voltage has been supplied to the grid and segments, even worse – after a few experiments healthy HT16515 was bricked due to unknown reason. We payed extra attention to its datasheet and to our surprise realised that the chip needed negative high voltage to drive segments, not positive and by applying any voltage higher than 0 to Vee we basically blew it up. Knowing about numerous typos in datasheets designed in Asian countries we simply overlooked that fact. After all, it didn’t look logical as everyone knows that VFD segments (anodes in fact) must have positive voltage in comparison with filament (known as cathodes). Now the whole project looked bleak as there was no place to take negative high voltage from… Or was? After many hours spent we finally figured out that yes, it would be possible to get negative high voltage if we reverse polarity of D1…D5 and C2-C6 and connect outer pin of D1 to GND instead of +5V forcing the voltage multiplier swinging in negative area. Yes, the absolute voltage wouldn’t be as high as we had originally (it was about +24V and now we can potentially get only -19V as filament AC is oscillating above zero, between 0.5V and 4.5V). But still it was a sound solution given that we had practically ruined the whole concept along with prototype.

The next problem immediately following the issue with negative voltage became filament AC voltage as now it was more positive than the negative one applied to segments/grids. Suddenly we understood the whole idea behind negative segment voltage. Surely, the VFD driver controls segments and grids by applying either zero or high negative (-24V) voltage, this probably gives some advantages when it comes to silicon chip design. But in order to make VFD display work, filament AC voltage should fall below ground as well and oscillate at around -20V or so. And to make a segment glow it would be enough to pull it to ground, to switch it off completely it should be pulled below the filament voltage so that way it will be even more negative than cathode. In reality it became apparent that there is no magic, same basic principles of VFD theory still work. To solve the issue with filament voltage we didn’t find a better way than to give up the idea of using AC generated by the filament driver and instead to scavenge it from the final stage of the voltage multiplier (between VS_MID and VS_MAX). Yes, it is not AC anymore, it is DC and there should be a resistor connected in series with VFD filament in order to dump excess of voltage a bit… ugly, but works for the first prototype at least.

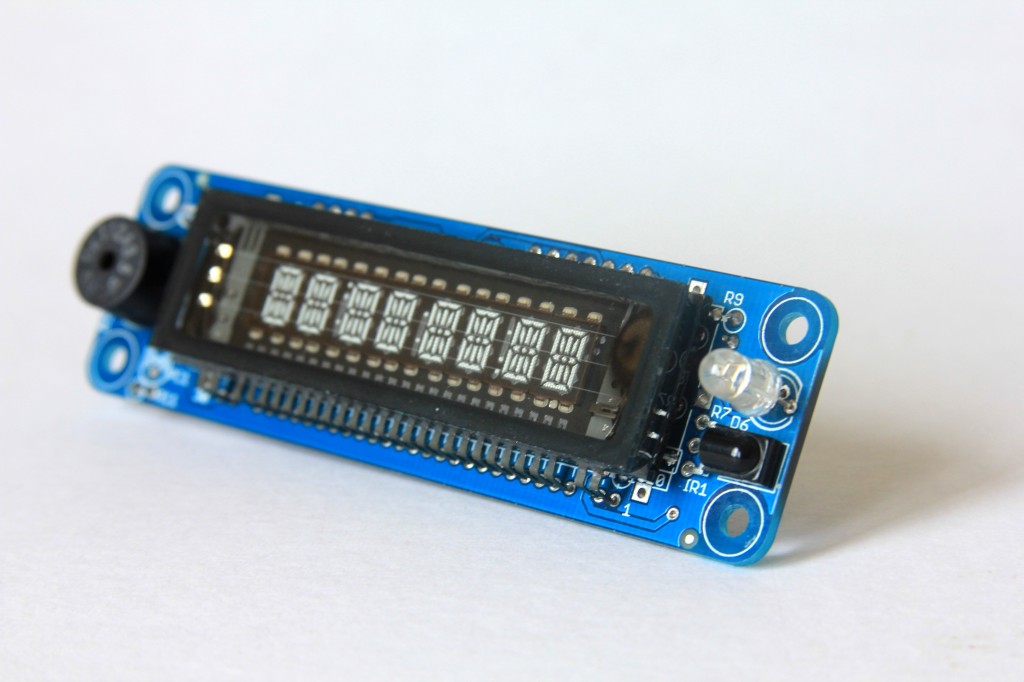

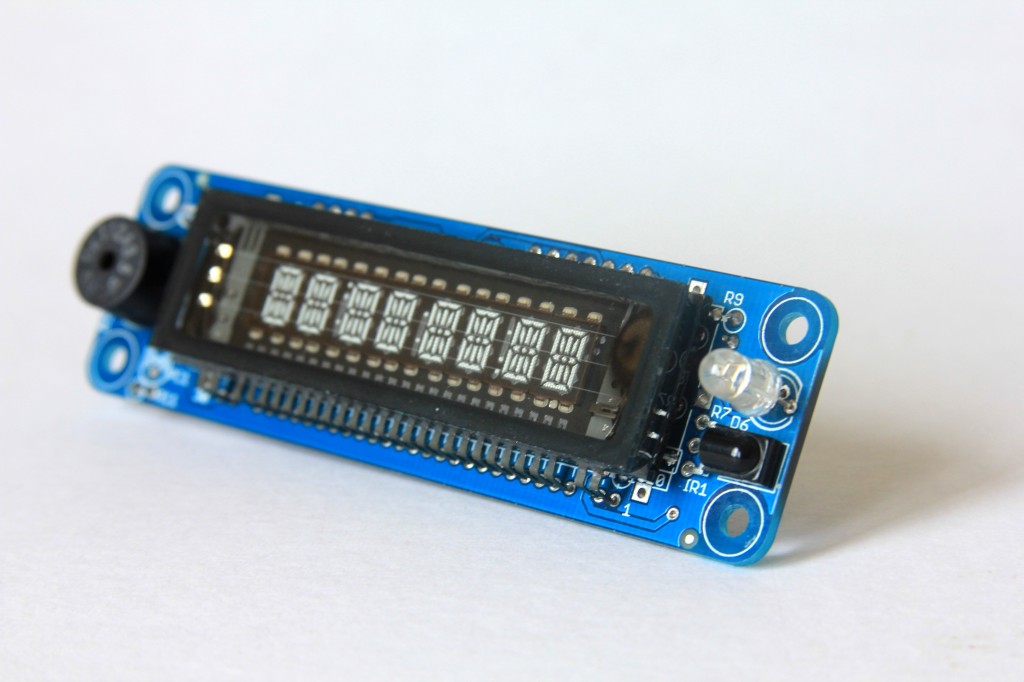

As a real proof of our ideas and efforts here are the pictures of working VFD panel below:

MVFD Panel 16S8D ISO View  MVFD Panel 16S8D Front View  MVFD Panel 16S8D Rear View  MVFD Panel 16S8D Front View In Action  MVFD Panel 16S8D ISO View In Action

What is the moral of this story? Design more carefully, make sure that not only design itself is sound but electronic components are readily available and not obsolete yet (although it is very hard to predict). And finally, never give up. Even if there are fatal mistakes in your initial design, there are still chances that they are solvable and therefore your prototype may come to life. In other words, all in your hands.

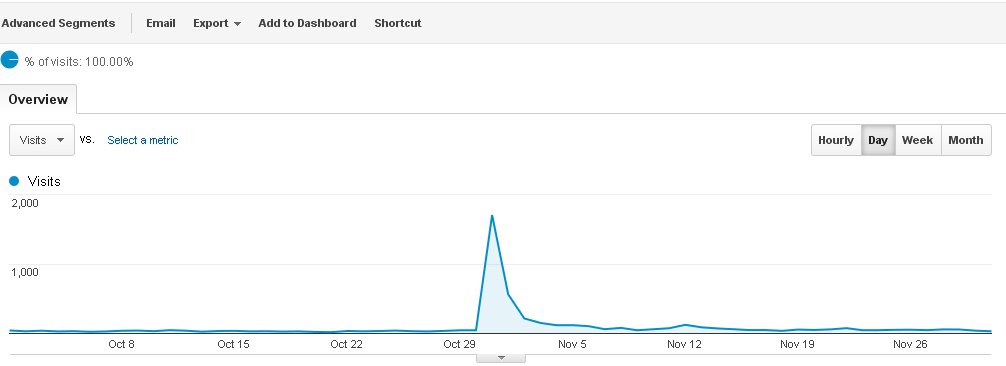

Today’s subject is rather irrelevant to electronics and programming however it plays a substantial role in the process of information delivery and virtually predetermines the fate of your project whether it is about electronics or software design or anything else. The importance of website promotion and optimisation is often underestimated by engineers especially by beginners and considered as ‘secondary’ after the primary goal – designing a great product. There is a common misconception that if you have a great tool/application then popularity and recognition will come without effort. Unfortunately, this world is far from perfectness and popularity does not necessarily come to the best and most deserved things. It means that promotion of an abstract project is no less important than its robustness/solidity/freshness/feasibility and so on. Another misconception is that many people are true believers in ‘magic formula’ that would allow to enter search engine’s top ratings by ‘giving your site proper settings’ and thus staying at the top virtually indefinitely long. Again, it is not about ‘magical settings’, it all is about content quality, its originality and update frequency, about non-standard approach, author’s proactive attitude and… yes, about luck. But let’s go through list of things that better take into consideration if you want to make more people to become aware of your new invention. Most of items seem to be obvious but surprisingly they are disregarded very often.

Let’s assume that you design a great electronic kit which is either so original and simple that there is no competitors yet or it is just cheaper than similar kits with the same functionality. Being carried away with your great invention you expect to see exponentially rising interest to your project. So you decide to create a web site which will back your kit with documentation, relevant discussions, software update and selling point. You buy a domain name and hosting, deploy content management system, customise it to fit your needs and at the same time to be original and catchy. You post carefully edited articles about your kit, tons of photos and design files and register it with google. And then you wait looking through Google Analytics every day, appending more articles, trying to find that ‘magic formula’. And what you see every single day? That is right, you’ve got 2-3 visitors on a daily basis. Or 5 as absolute max. And what you also discover, those visitors spend just 1-3 minutes (!) on your web site and them most of them never return again. What is daunting, posting new articles does not increase the amount of visitors – it is just enough to keep your site from stagnation. Sounds familiar? Let try to analyse what is actually happening.

First of all, people just don’t know about your website and project. Especially when it comes to electronics, people are crowding at popular and well-known hubs and the probability of stumbling upon your site is very low – you have to advertise your resource but because you just started your activities you just can’t afford it due to the lack of financial means. Secondly, if your project is too original people won’t be able to come across it just because they… don’t search for it! And the reason why most of the visitors never returns again is simple – they are not interested in your content because they are not in your target group.

In order to solve at least some of the abovementioned problems tactics needs a slight change. You still can have your own website but it is absolutely vital to build up links to your site from well-known and heavily visited respected resources. For example, let’s consider an example of a ‘do-it-yourself’ (DIY) project. You design a working prototype and thoroughly document it. Then you submit it to Instructables.com sparkling discussions and at the same time exposing it to a tremendous amount of people from your target group. Of course, in your description you provide links to your site and if a person finds the project interesting he/she would consider it worthwhile to visit your website. Some resources won’t allow to submit a project instead they might be notified about its existence then they scrutinise a project and publish it if it is considered interesting and original enough. Sometimes there is opportunity to submit your project to contests and get extra visitors and even prize if lucky enough. But at the end of they day all this can give a tremendous boot to your website and your own self esteem – just enough for you to keep doing good work.

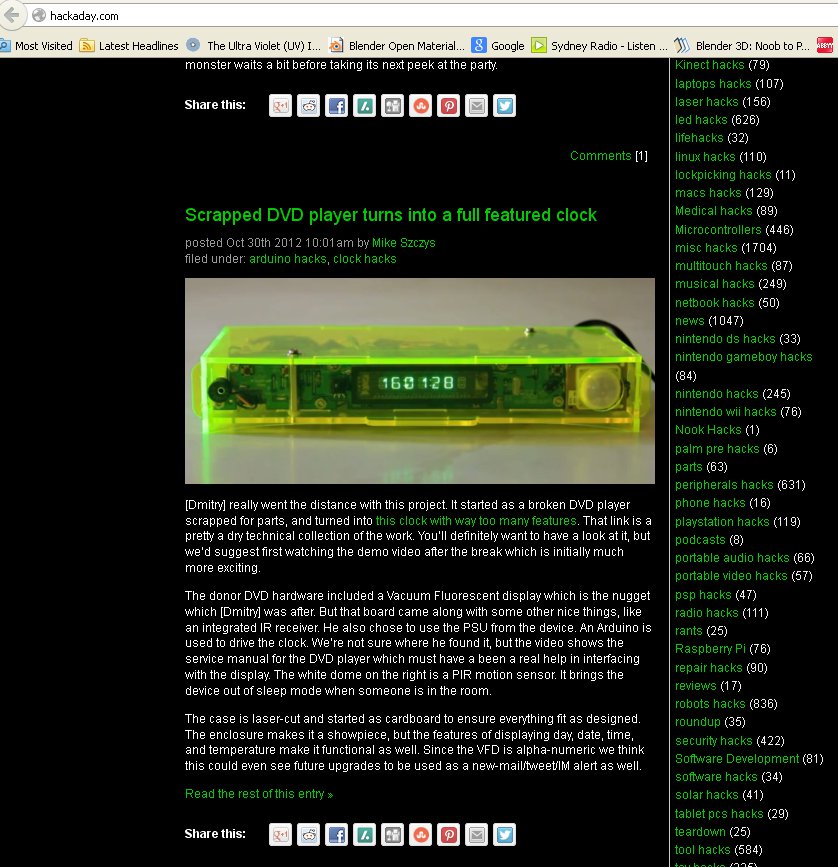

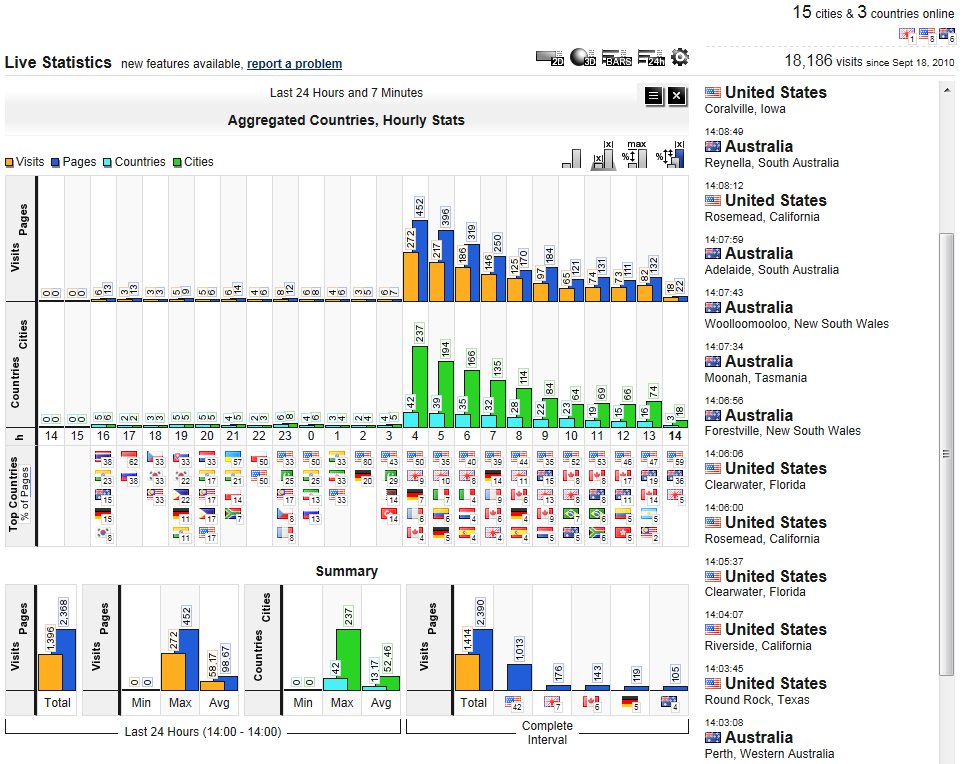

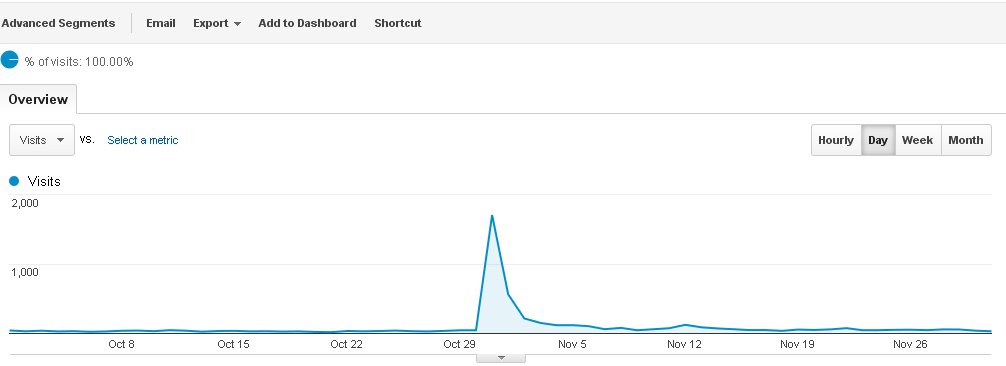

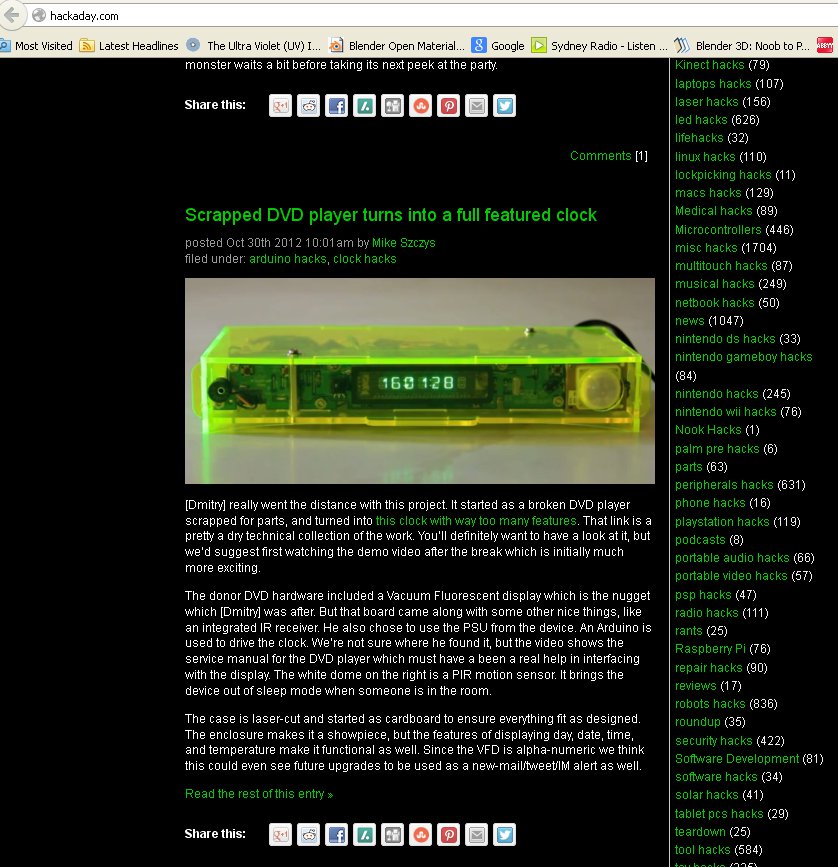

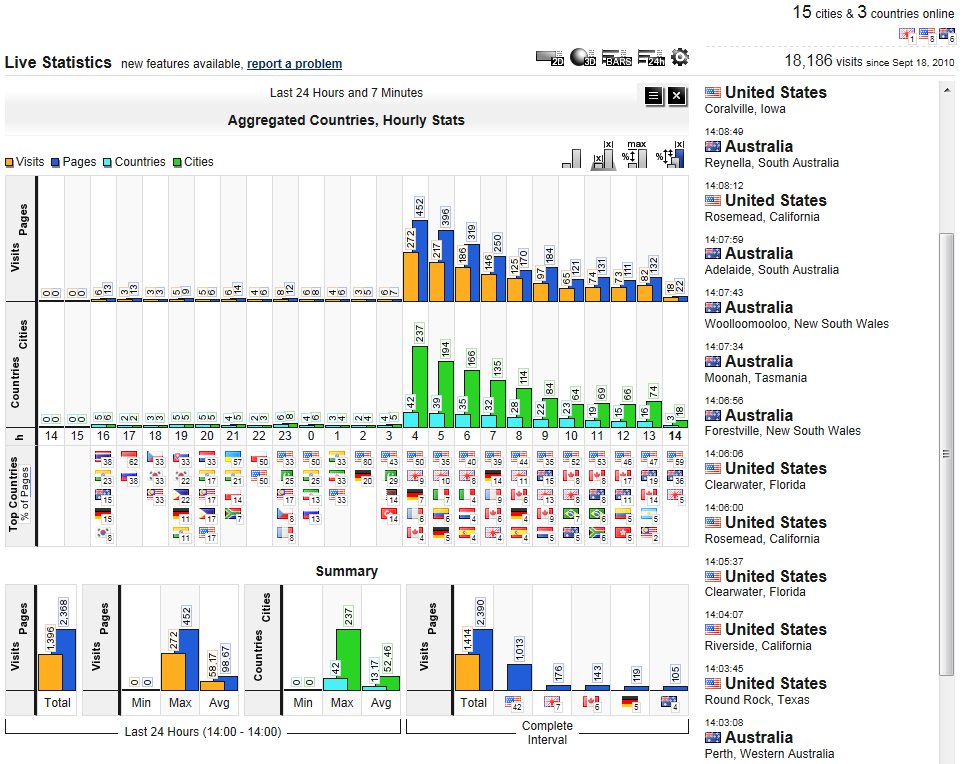

Here is an example of how publishing our project at Hackaday.com and Instructables.com helped us to increase number of visitors.

VFD Clock at Hackaday.com  Visitors from hackaday.com  Google Analytics Hackaday Boost

These are PCBs recently manufactured for a VFD project. Aiming at very small initial quantity and rather compact 100×25 mm dimensions BatchPCB was considered an ideal service for making our PCBs. But in the end it turned out that shipment from US would be ridiculously expensive and simply not being worth ordering. That was the turning point when ITead Studio has been discovered. The company offers very attractive deals for small PCB batches and especially prototyping but in order to take full advantage of their prices PCBs dimensions should somewhat correlate with the factory’s blank sizes. That way even greater economy might be achieved significantly cutting down expenses for prototyping and small runs.

So what is so special about the service from ITead Studio? To begin with, they have a bit different approach by providing certain number of blanks with predefined sizes, let’s say, 100×100 mm, 100×50 mm, 50×50 mm and so on. A customer is offered to buy a service, for example, 10 blanks of 100×50 mm with specific parameters such as material type and thickness, mask and silkscreen colours etc. And then after uploading PCB design in Gerber format the factory house takes care of everything else. For instance, they do panelisation by themselves, without even asking you. In our case, having ordered 100×50 mm service and PCB dimensions 100×25 mm we ended up not with 10 but 20 PBCs, they just silently managed to fit two PCBs on each blank!

The prices are very attractive, for 100×50 mm service they ask just $25 (or even $22 if you’re happy with green color for the mask) for 10 (or even more depending on how many PCBs can fit on one blank) PCBs. Another significant advantage is an absence of tooling fee which brings the overall cost to a level way less than $100 which was literally impossible until now.

Add to this friendly e-mail notifications, really short lead time (just 7 days), and an option to choose really cheap shipment which by the way is not that slow, took two weeks in our case to deliver a parcel from Hong-Kong to Australia and cost us less than $6. Indeed, PCB manufacturing has never been so affordable for hobbysts as it is now.

MVFD Panel 16S7D PCBs

|